WHAT WE OFFER – SERVICES & MANUFACTURING

We know the expectations of your industry and we understand your needs. If we get involved right from the start and we supply you with a final solution with highly qualified and motivated employees and our engineering tools, we make it much easier for you to finalize your design, your products and your systems. We will design and offer you the right solution for your requirements. Contact us and we will develop an individual solution for your needs.

We are committed to a very high level of quality, accuracy and efficiency. The close contact to our customers ensures the constructive cooperation with the aim to accelerate project development. We have a strict procedure for our self inspections to guarantee the ongoing improvement of our processes.

We are specialized in customized manufacturing of high performance divers catheters for medical OEMs, contract manufacturers. We are committed to delivering value by developing innovative, high performance solutions for your medical devices needs with our expertise to solve technical challenges. Our mission is to work together with you to achieve the key goal of improving reliability and performance of your medical product from the original concept to the market introduction. We view ourselves as an extension of your team. When the others tell you an idea can’t be manufactured, we view it as a challenge. Our team works hand in hand with you to convert your idea into a prototype. We go through development with you to arrive at a prototype design that delivers what you want with optimized manufacturability. At the next stage, the initial prototyping undergoes testing and inspection, providing data we use to move toward a more efficient design, which we translate into a next generation prototyping with a high focus on performance and better manufacturability with cost effective production.

We provide a full range of solutions to support research and development of electrophysiological catheter, diagnostic mapping, ablation, and accessory products for catheter-based treatment of cardiac arrhythmia’s solutions to support every phase of the product life cycle of catheters.

STRUCTURAL HEART CARDIAC RHYTHM MANAGEMENT & ELECTROPHYSIOLOGY

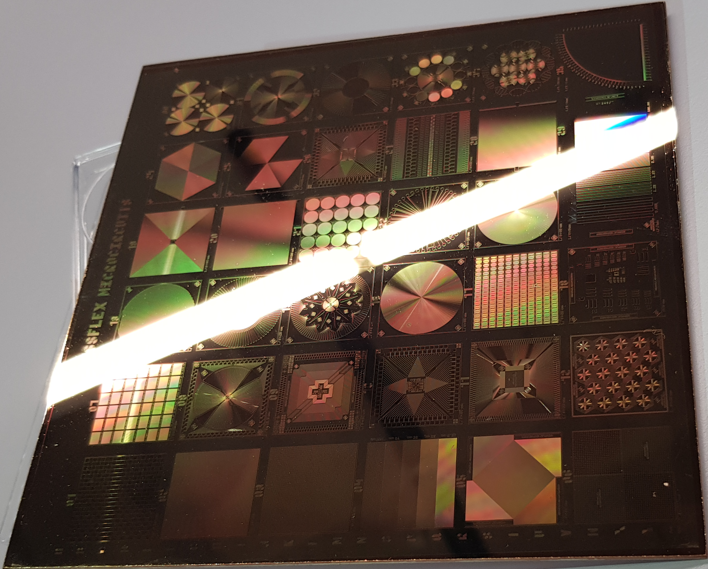

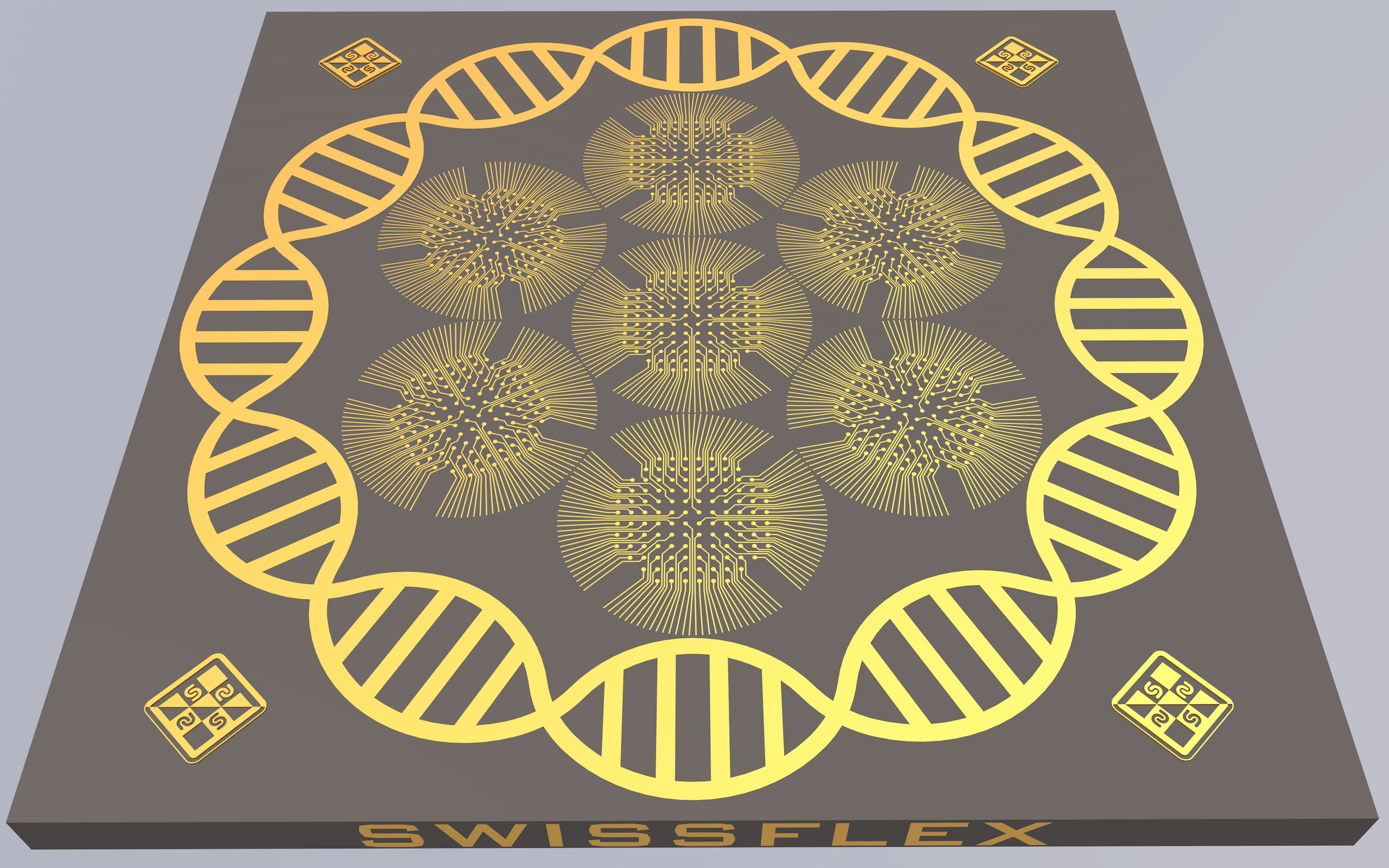

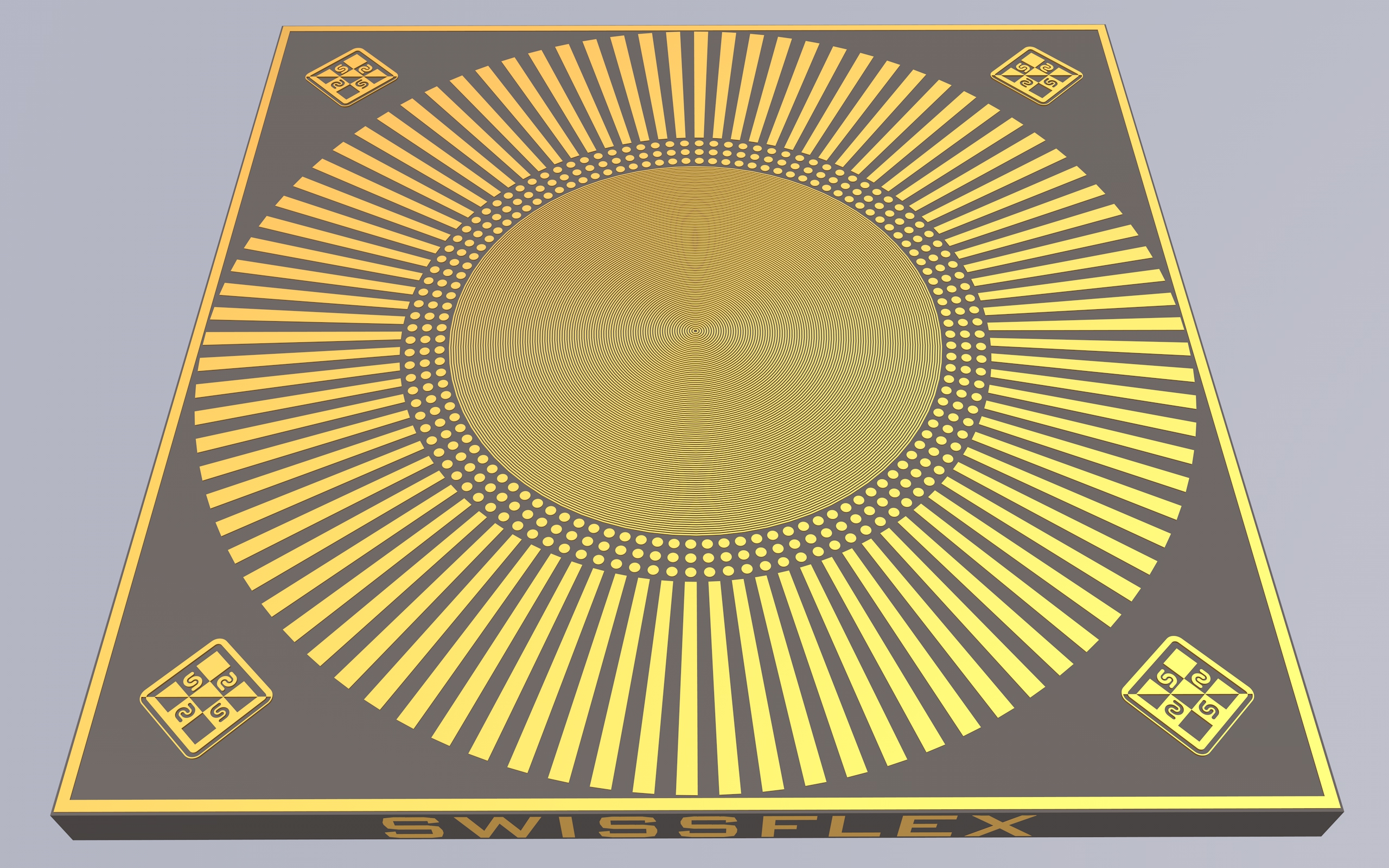

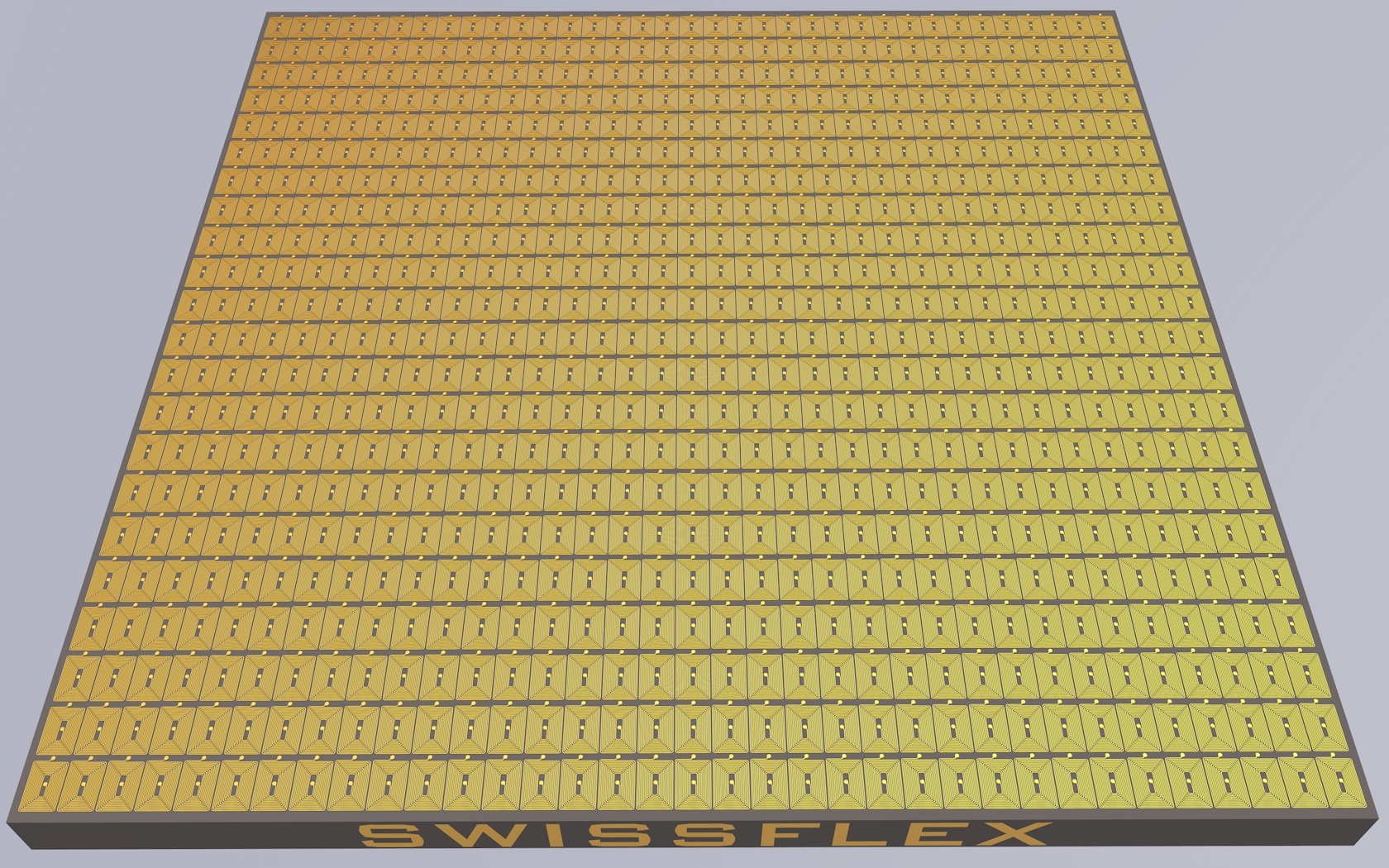

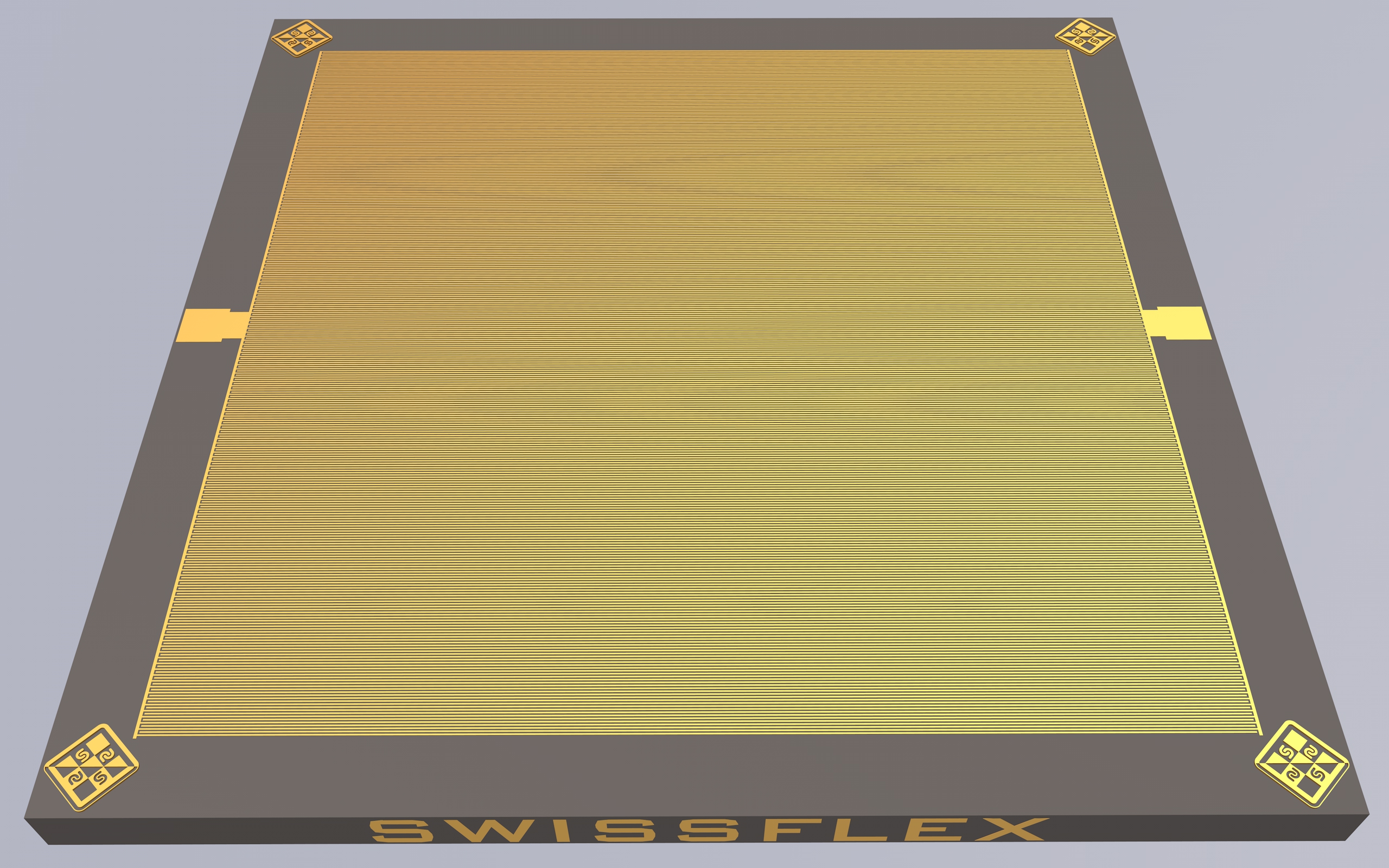

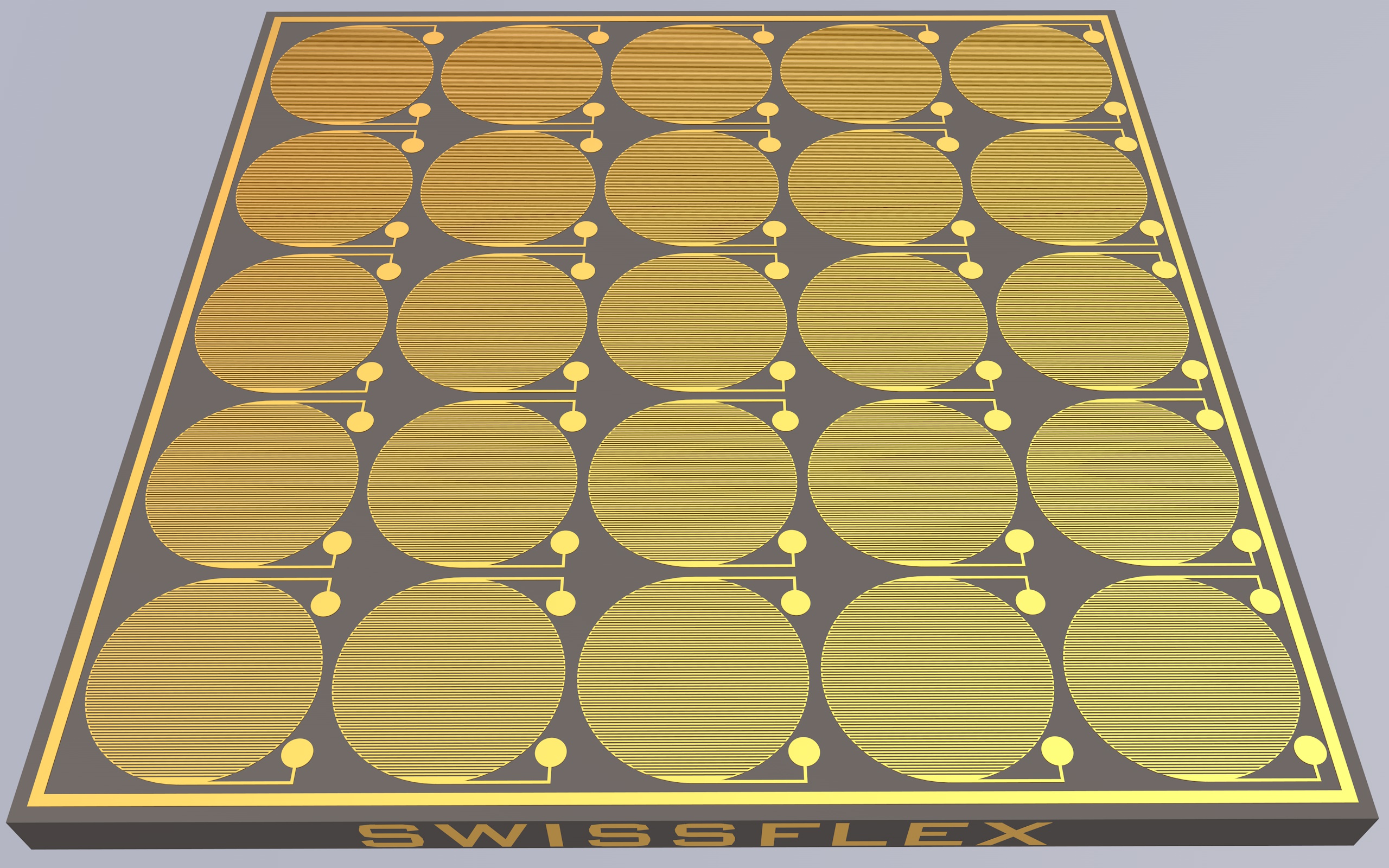

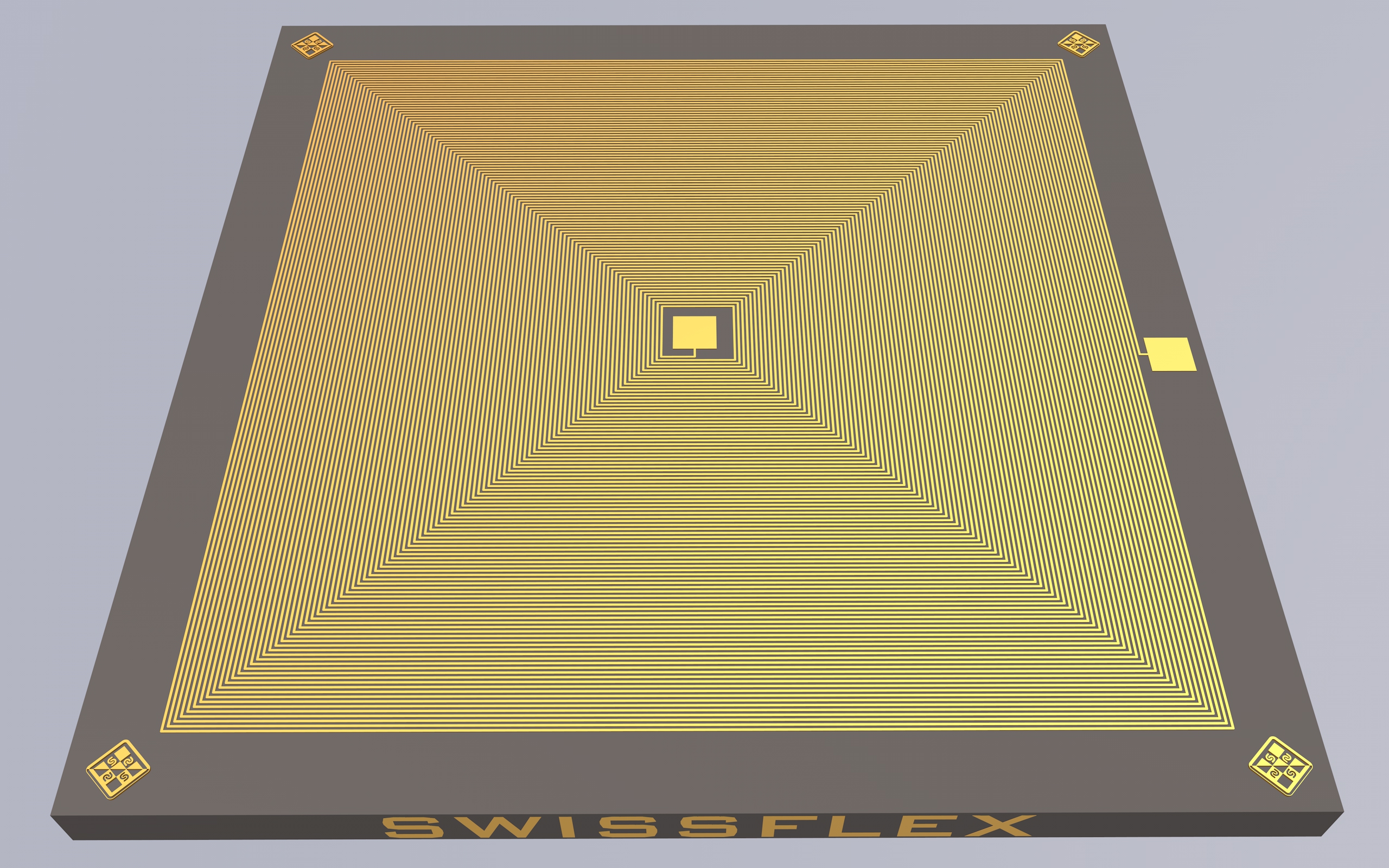

MICROELECTRODES ARRAYS for extracellular electrophysiology Microcircuits on Thin Glass, Polyimide, PET, Parylene, Ceramics

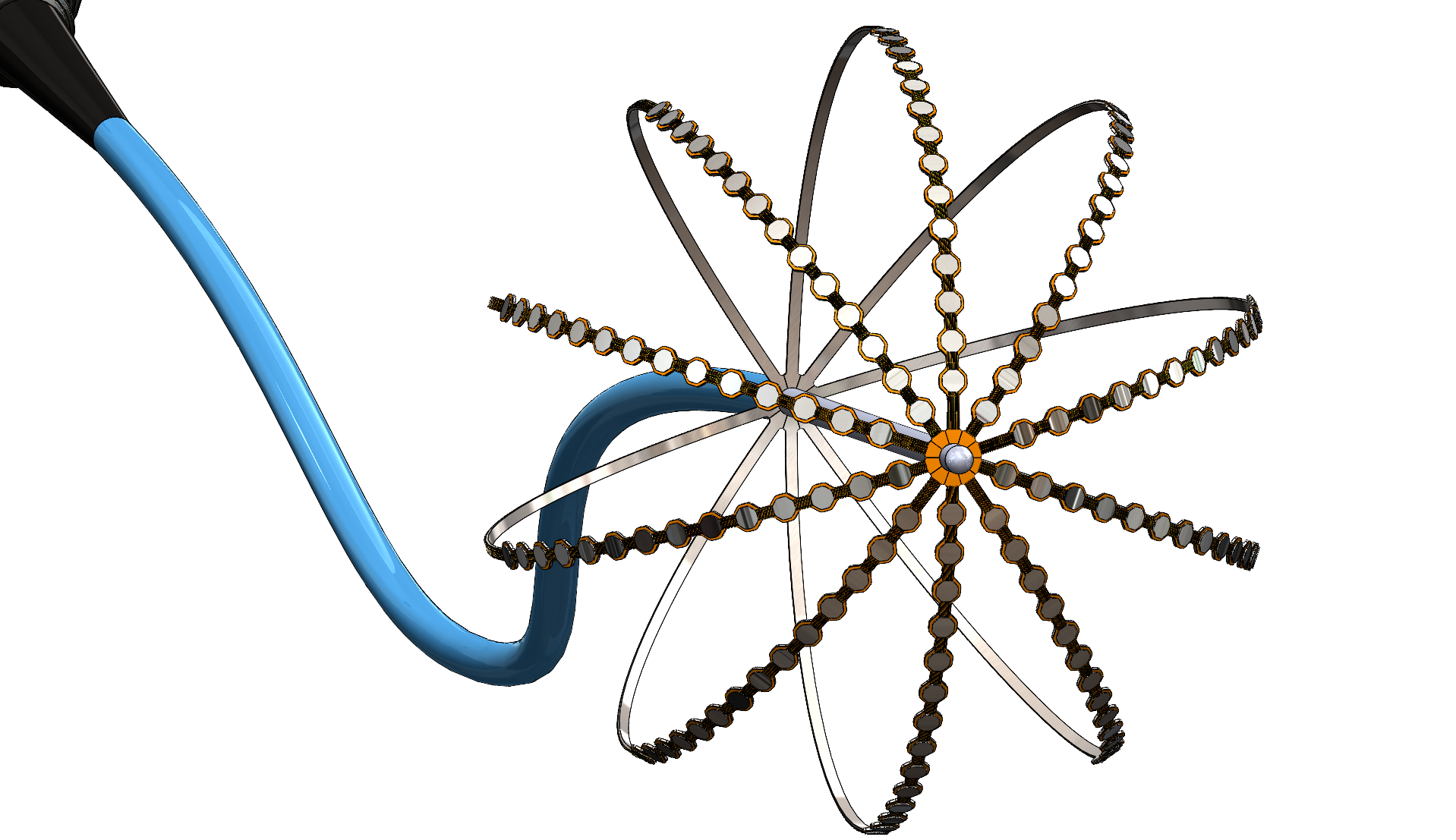

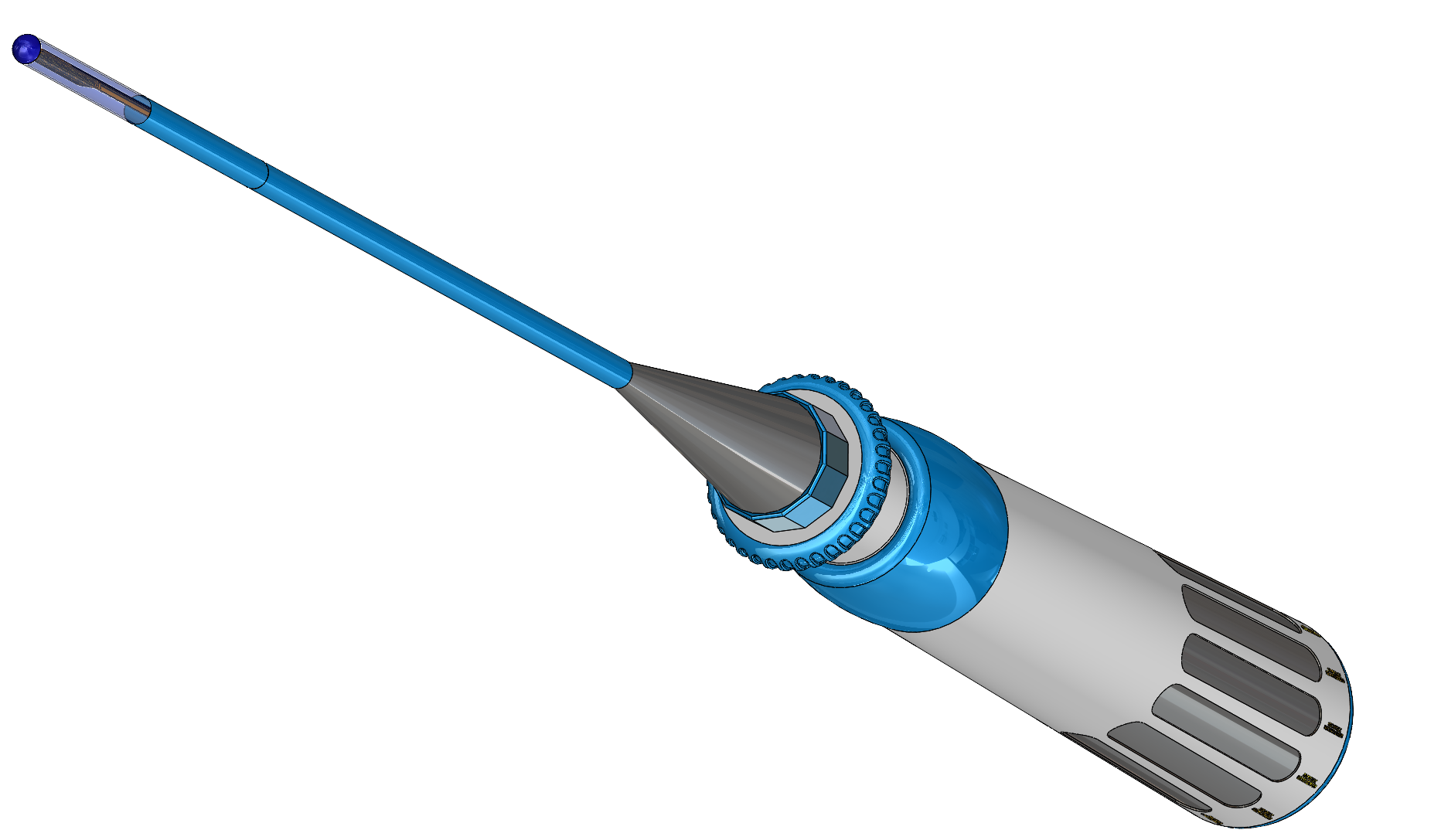

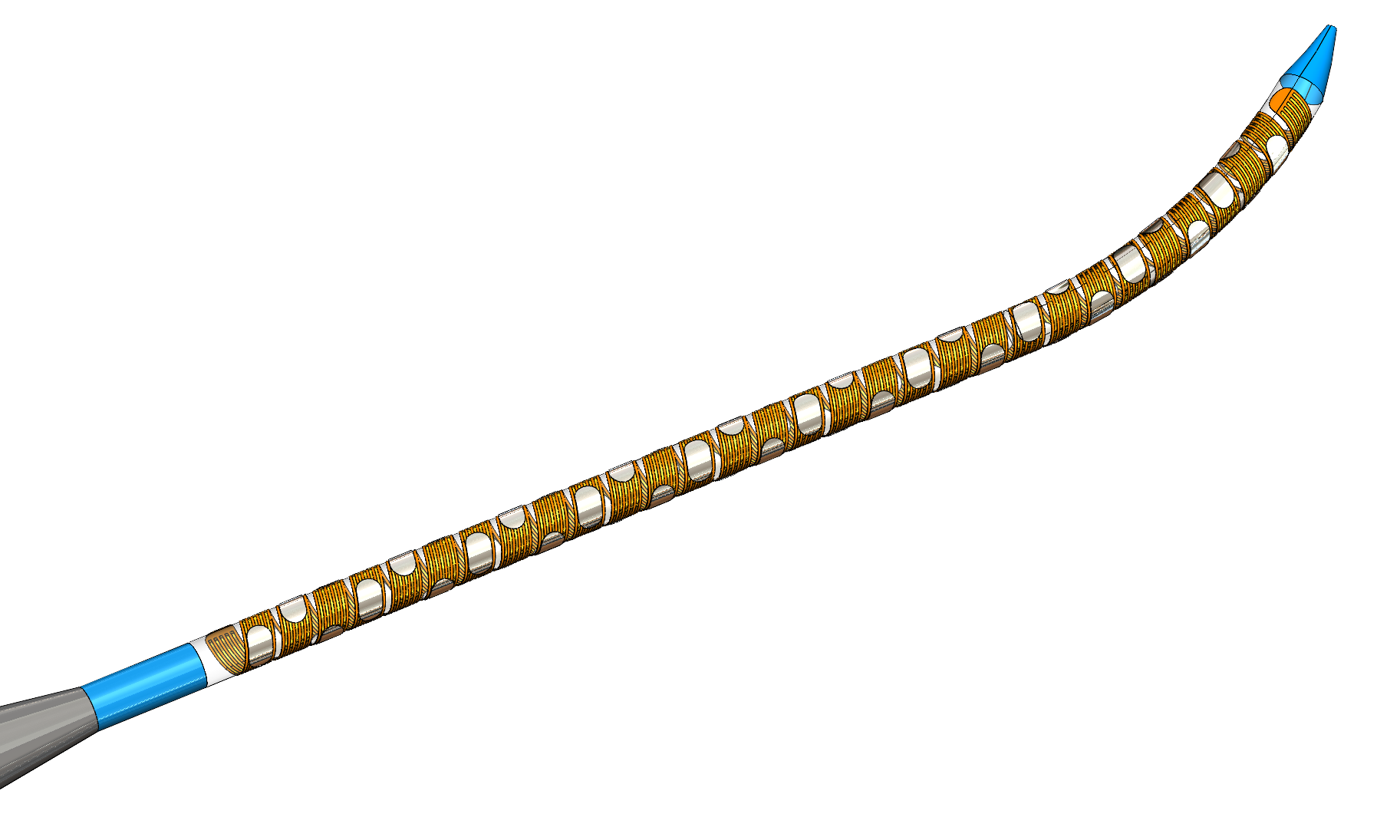

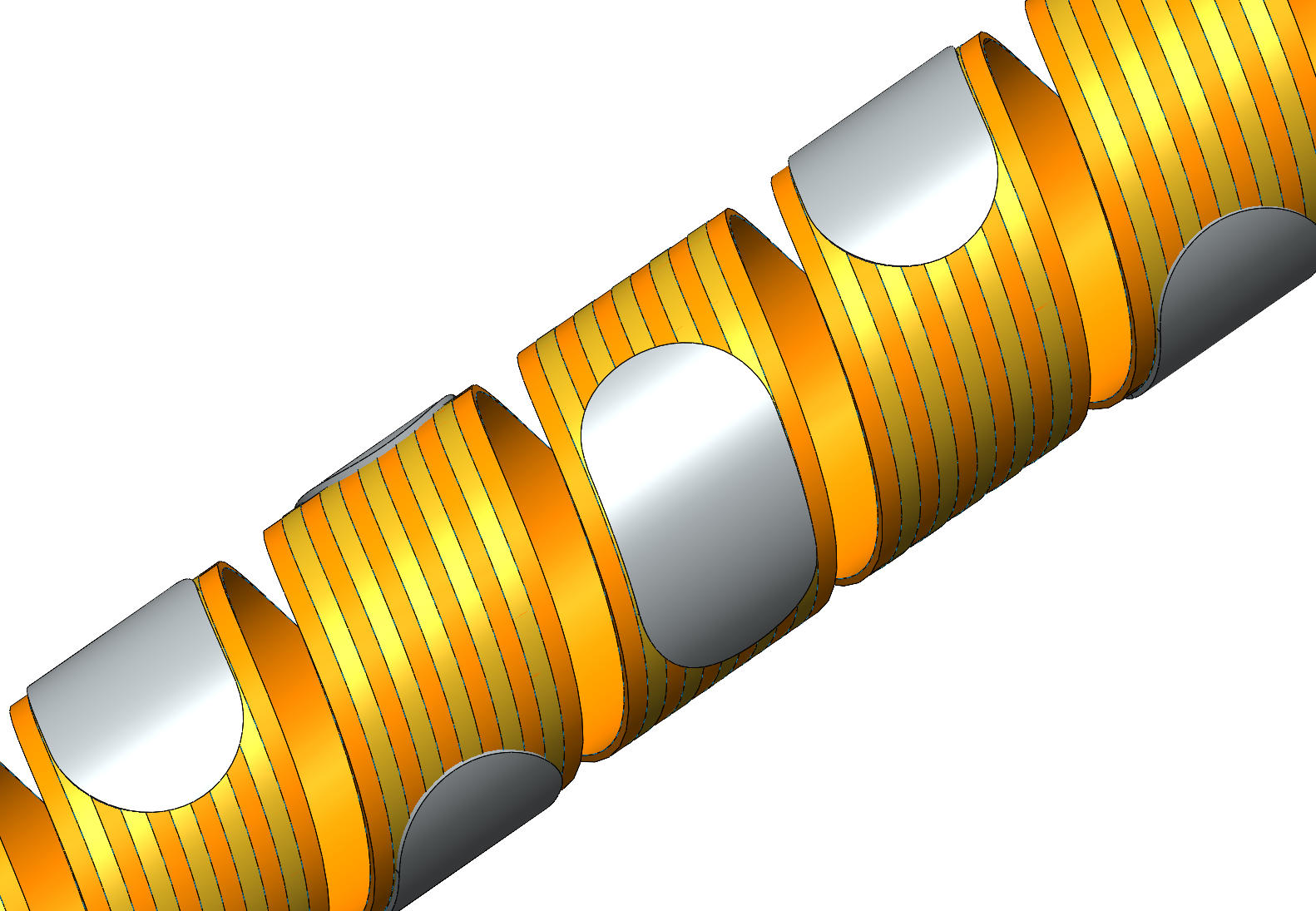

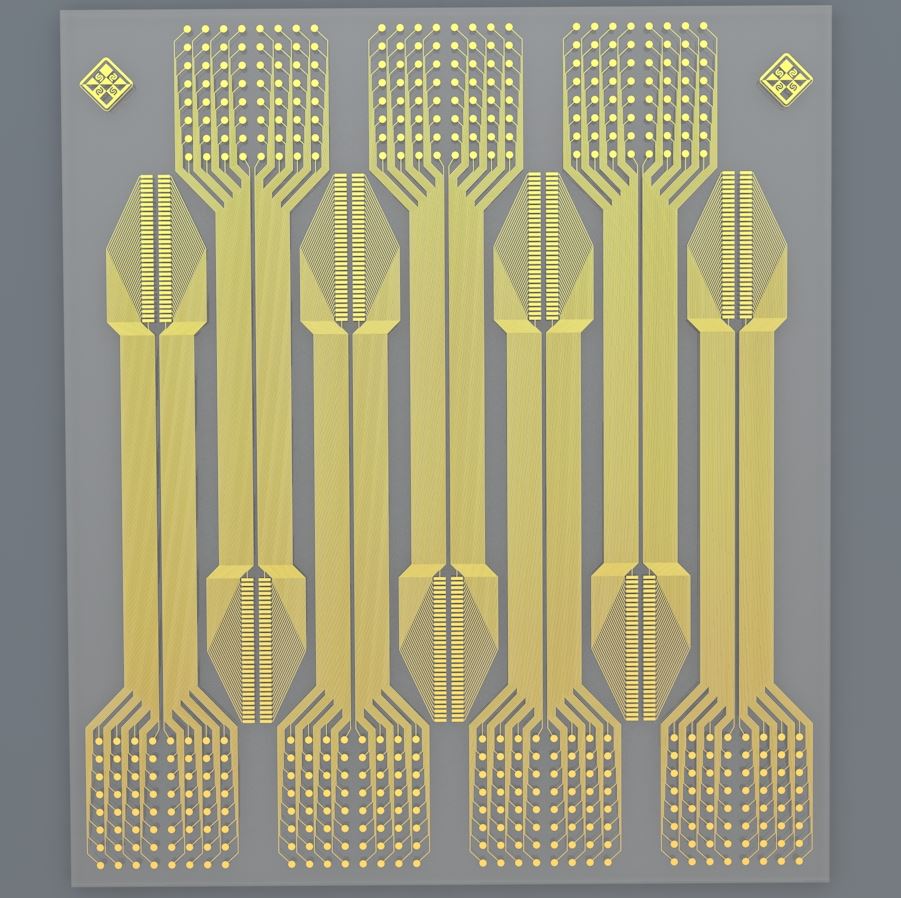

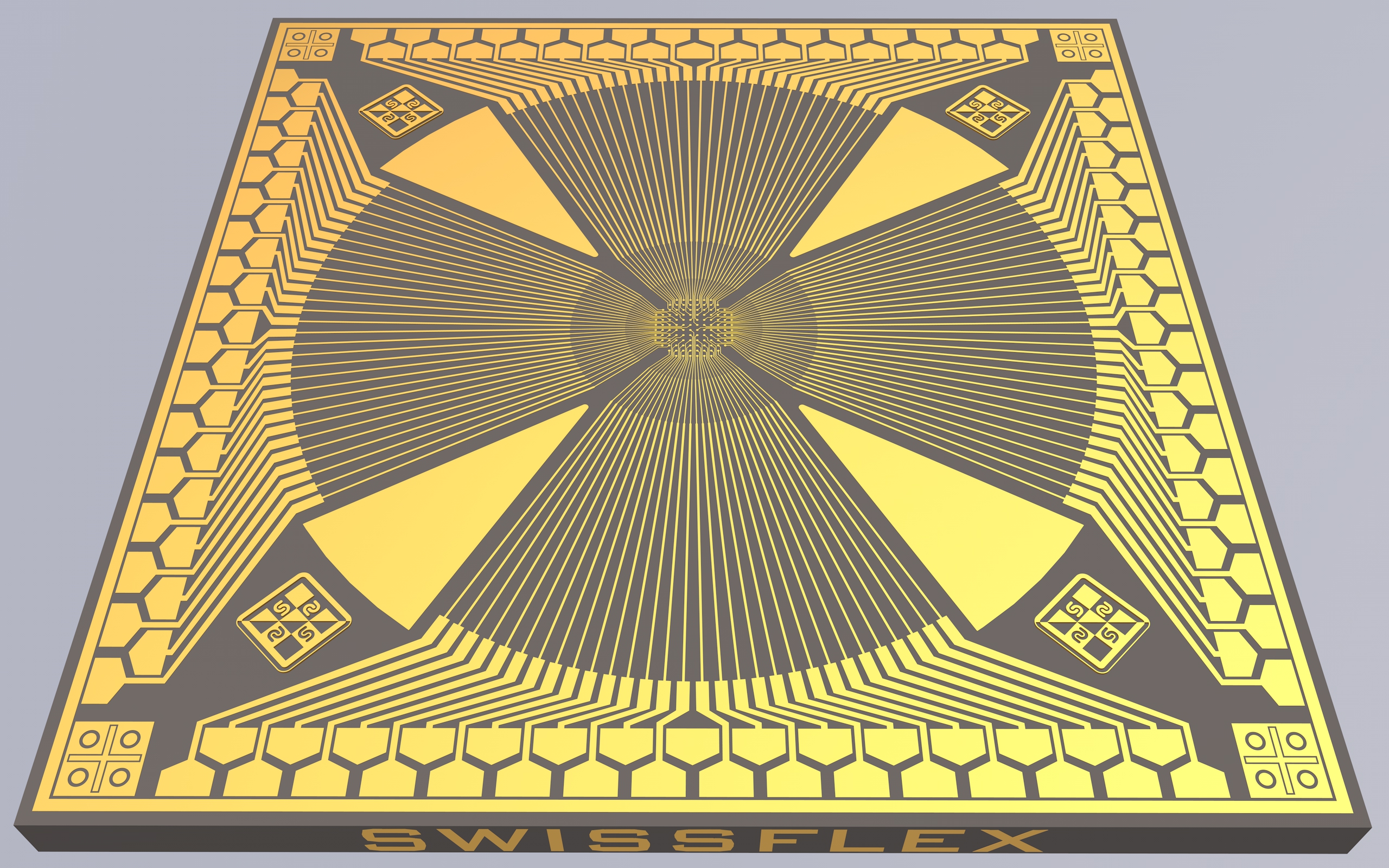

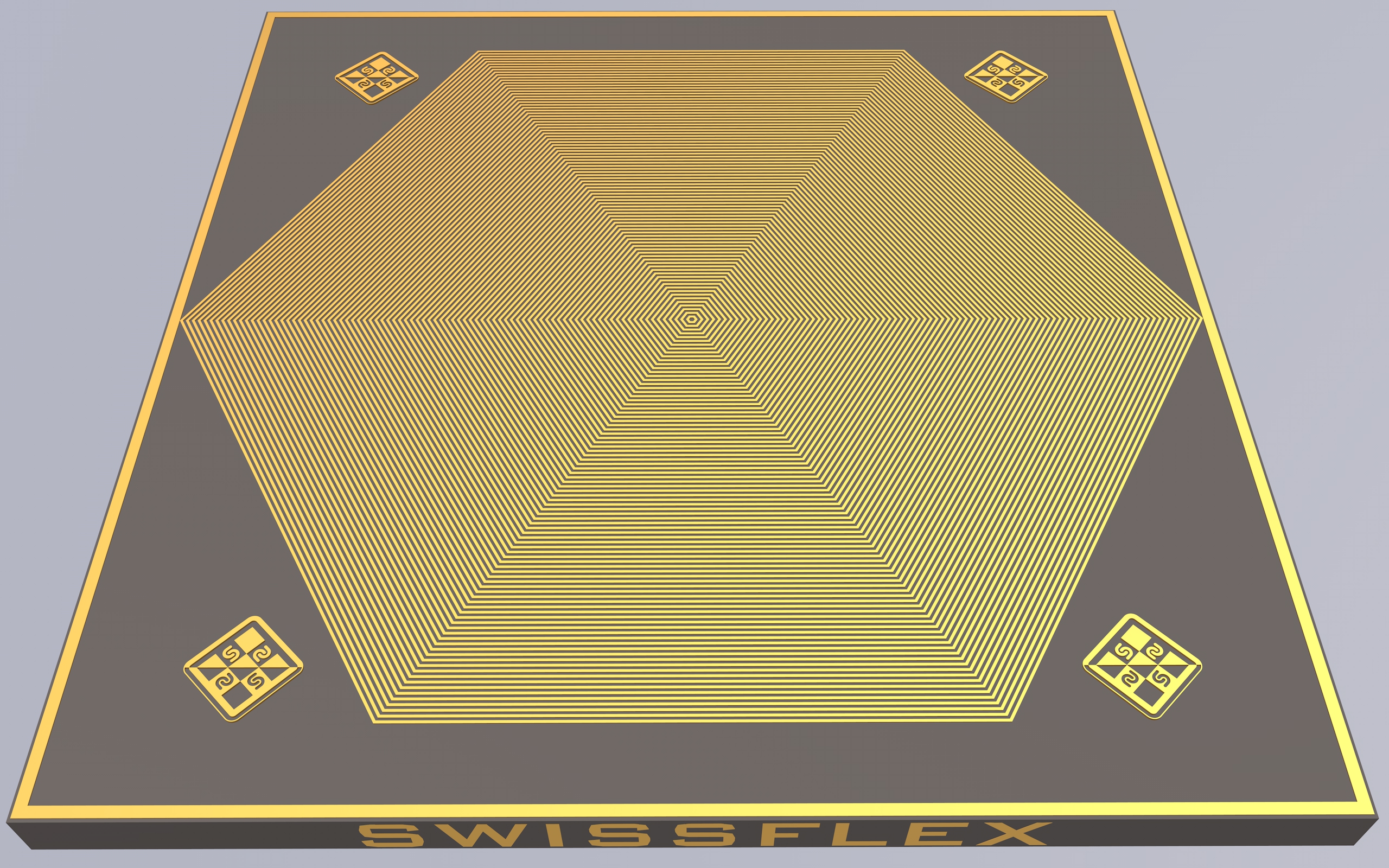

MAPPING CATHETERS (Long flexible circuits with high density electrodes constellation and long interconnection flexible cables for Mapping Catheters solutions)

ABLATION CATHETERS (Long flexible circuits with high density electrodes constellation and long interconnection flexible cables for Ablation Catheters solutions)

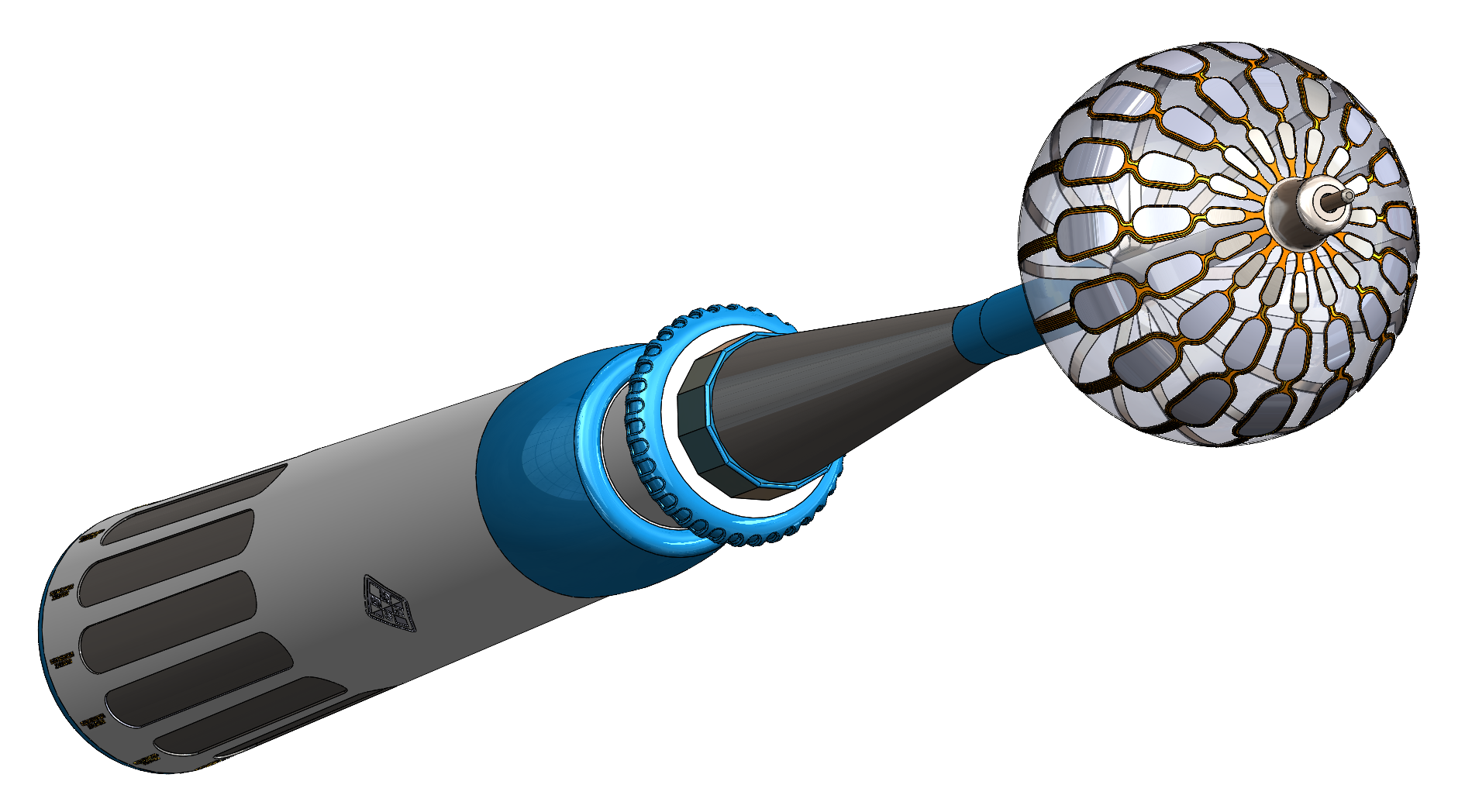

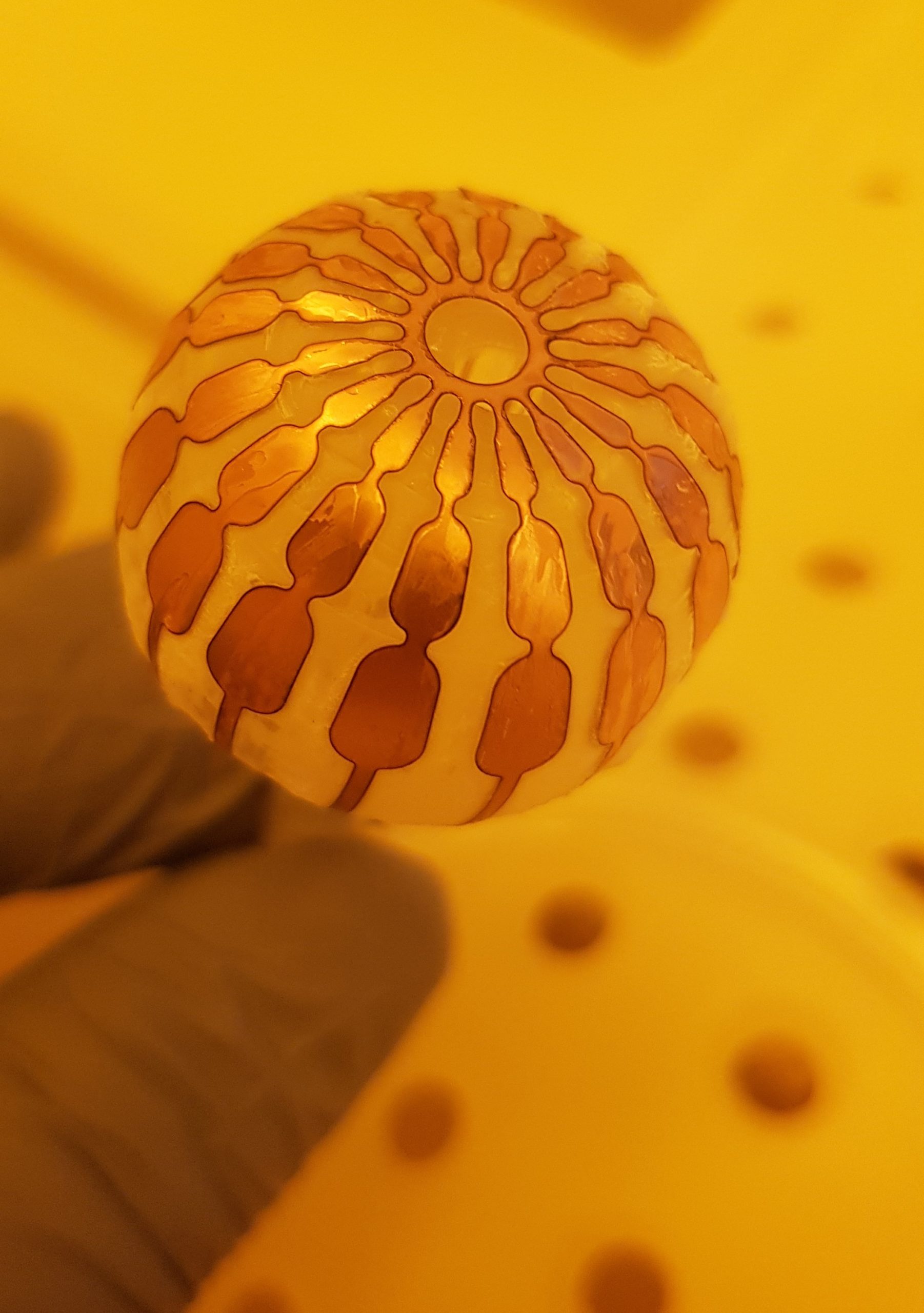

BALLOON CATHETERS (Long flexible circuits with high density electrodes constellation and long interconnection flexible cables for Balloon Catheters solutions)

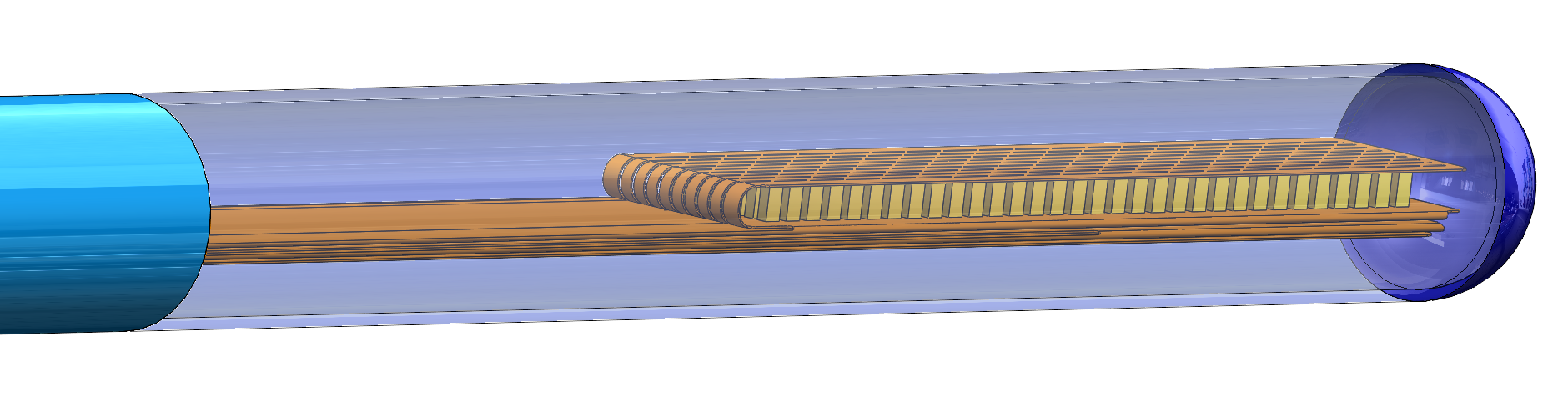

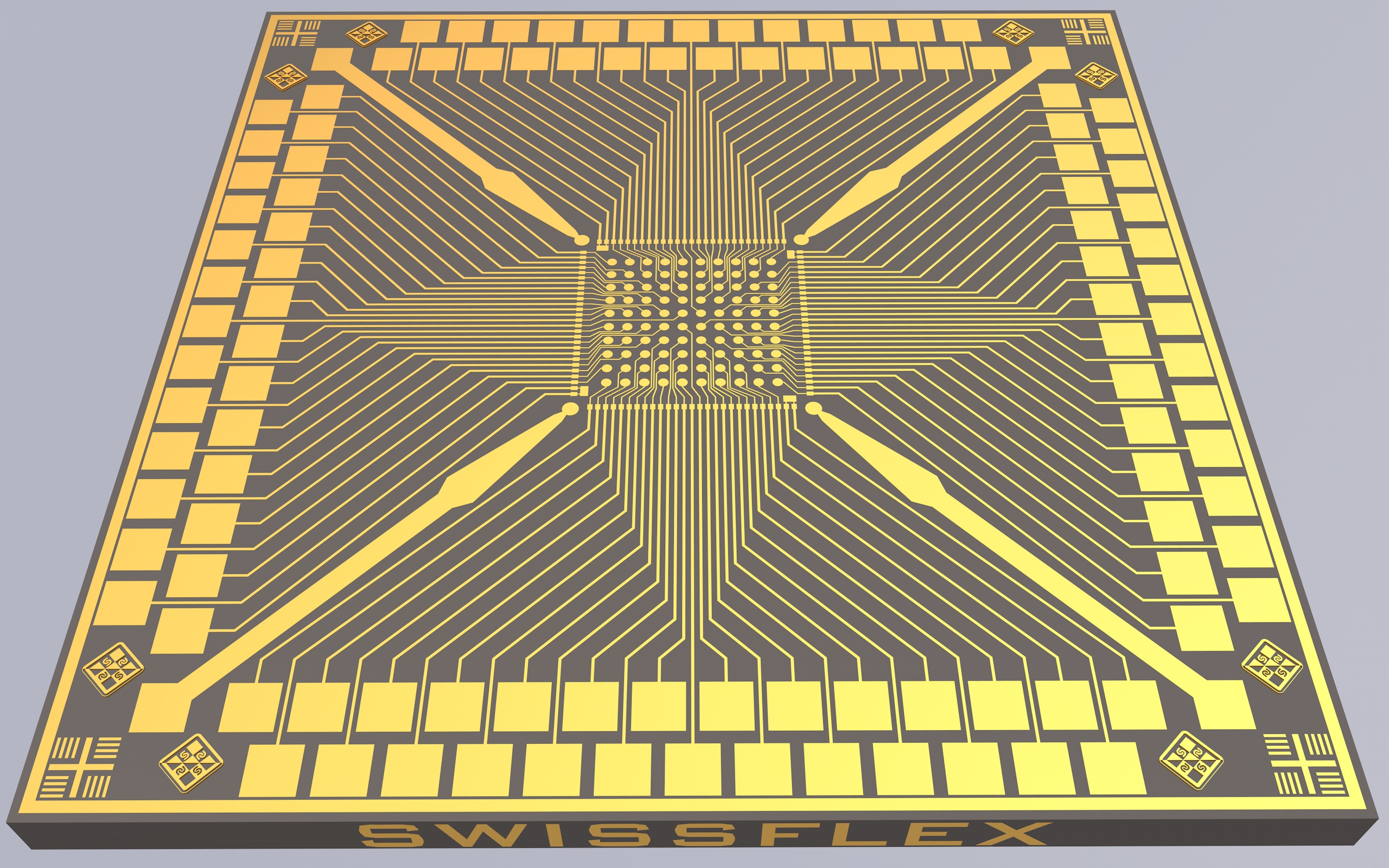

ICE CATHETERS (Long flexible circuits with high density 256 Piezo Arrays in 8F Catheter and long interconnection flexible cables for ICE Catheters solutions)

PLACEMENT DEVICES (Micro scale device, Nitinol Micro structuration, Balloon,…)

INTERVENTIONAL CARDIOLOGY & RADIOLOGY

High Density Flexible Microelectrodes Arrays for Imaging & Diagnostic Catheters

High Density Flexible Microelectrodes Arrays on Balloon Catheters

Procedural Devices

LUNG CATHETERS

Diagnostic & Wrapped Multielectrodes Arrays 8F Lung Catheters solutions

NEUROVASCULAR

Microflexible HDI Catheters

Epilepsy Implant Devices

Microcoil Systems

Neuroablation Devices

Neurostimulation Devices

GASTROINTESTINAL

Long Endoscopes with Ultra Long Flexible Microcircuits

Ablation Catheters

Esophageal Devices

Dilation/Balloons

Urology Devices

Gynecology Devices

We are leading medical device companies to provide design, engineering and medical manufacturing solutions ranging from complex, finished devices to components that meet stringent quality and regulatory requirements.

New products development for medical devices projects from concept through commercialization through our proven process roadmap. We are always pleased to take on new challenging projects.

Whether you’re looking to private label a new and innovative device, improve your next generation catheter and delivery system, or reduce time when building new feature sets into your products, our design and manufacturing processes solutions can meet your needs.

We offer end to end contract medical device manufacturing services. We are leading contract development and manufacturing organization of device such as experience developing and manufacturing complex endoscopy and catheters for medical devices systems for demanding applications.

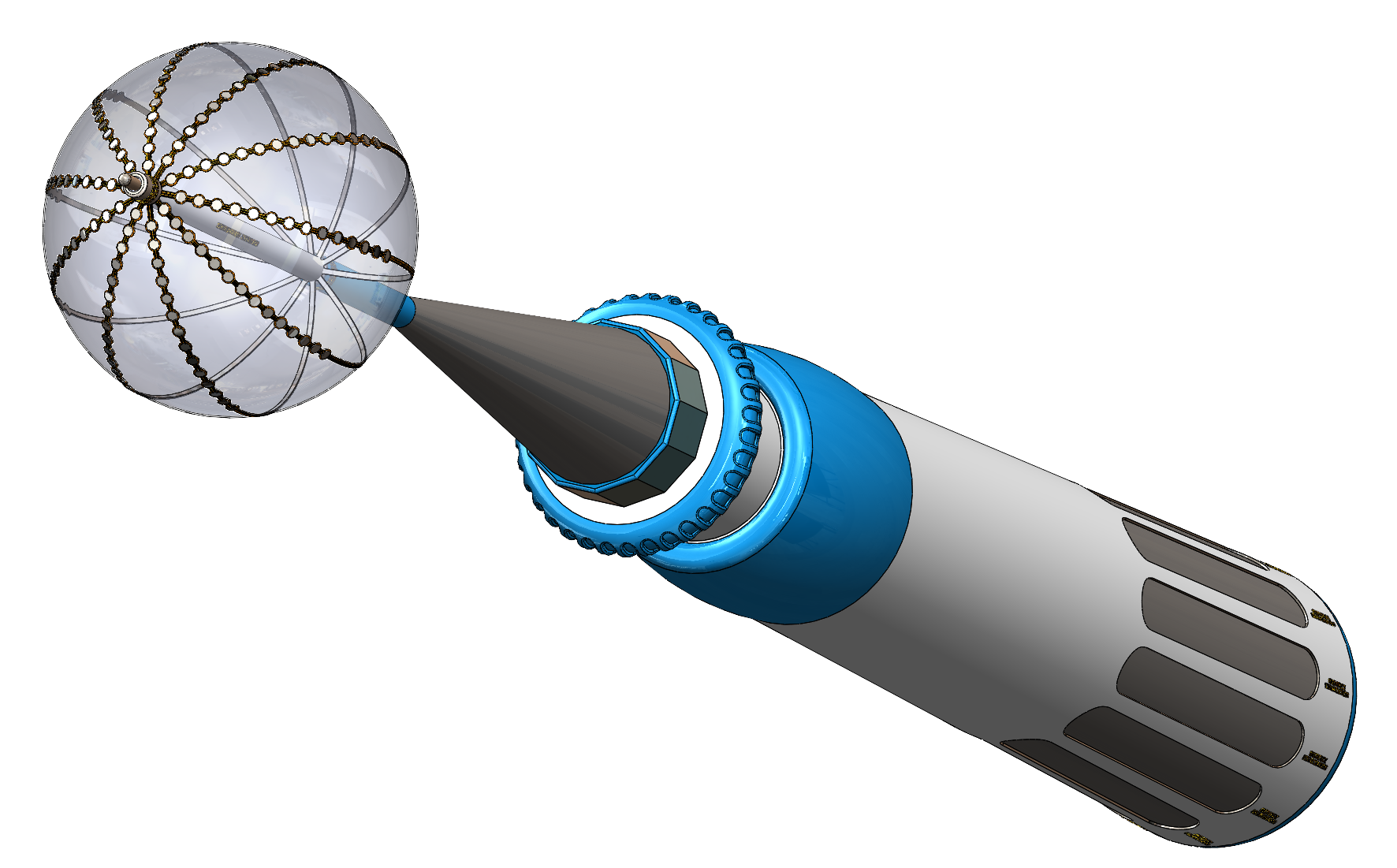

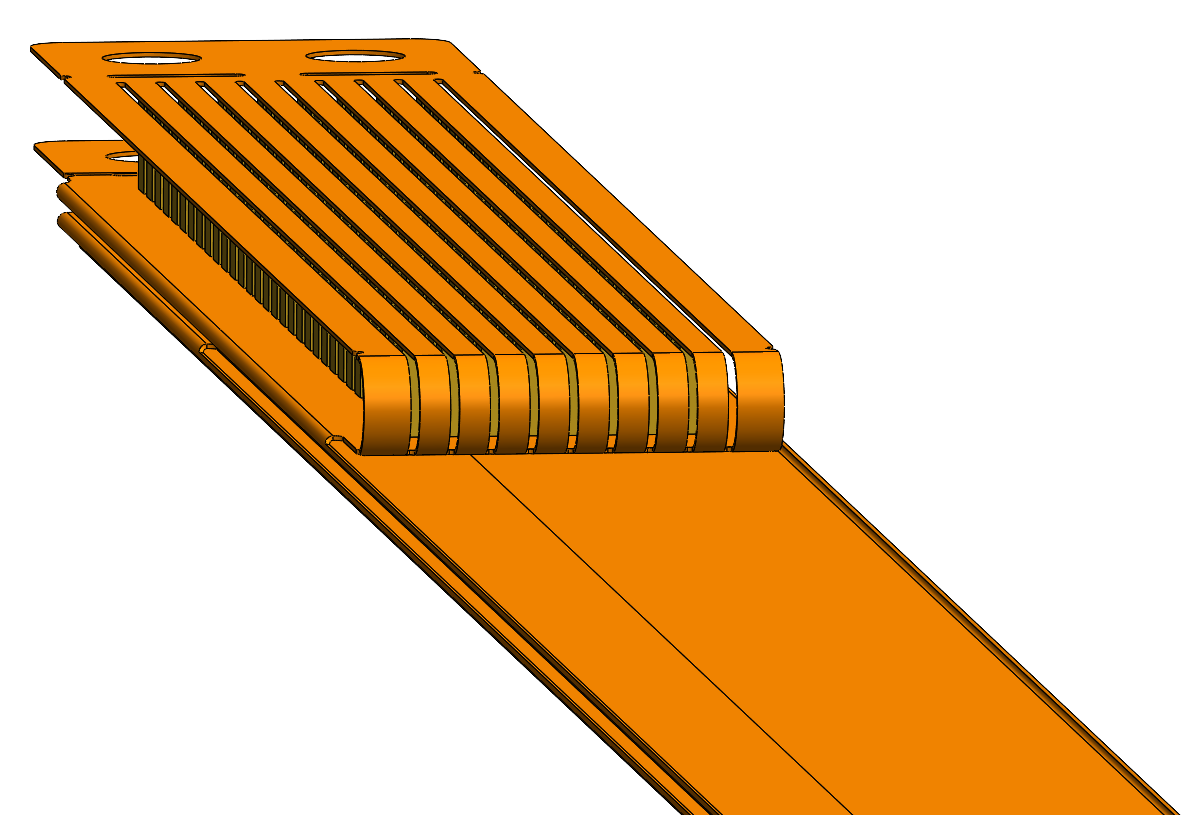

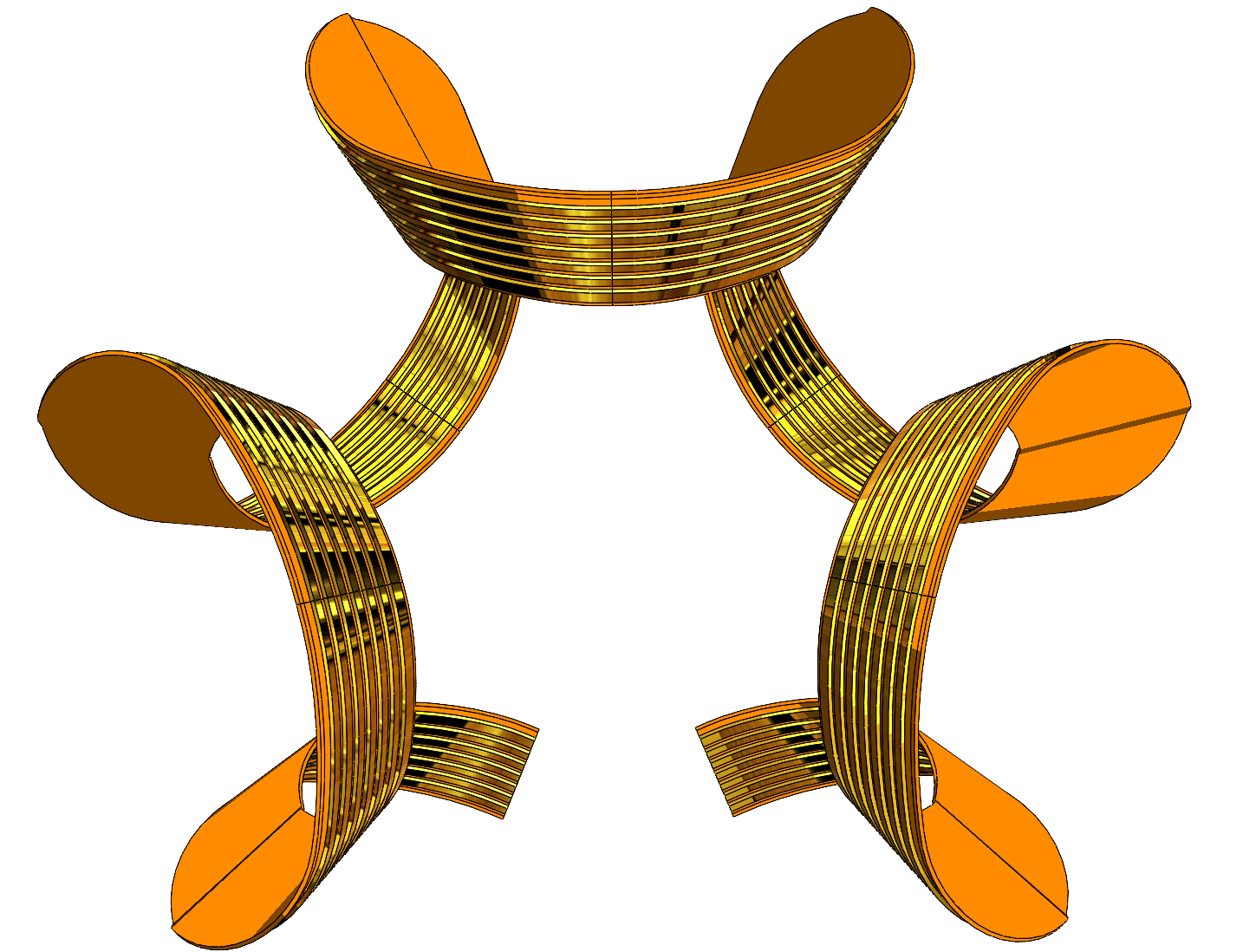

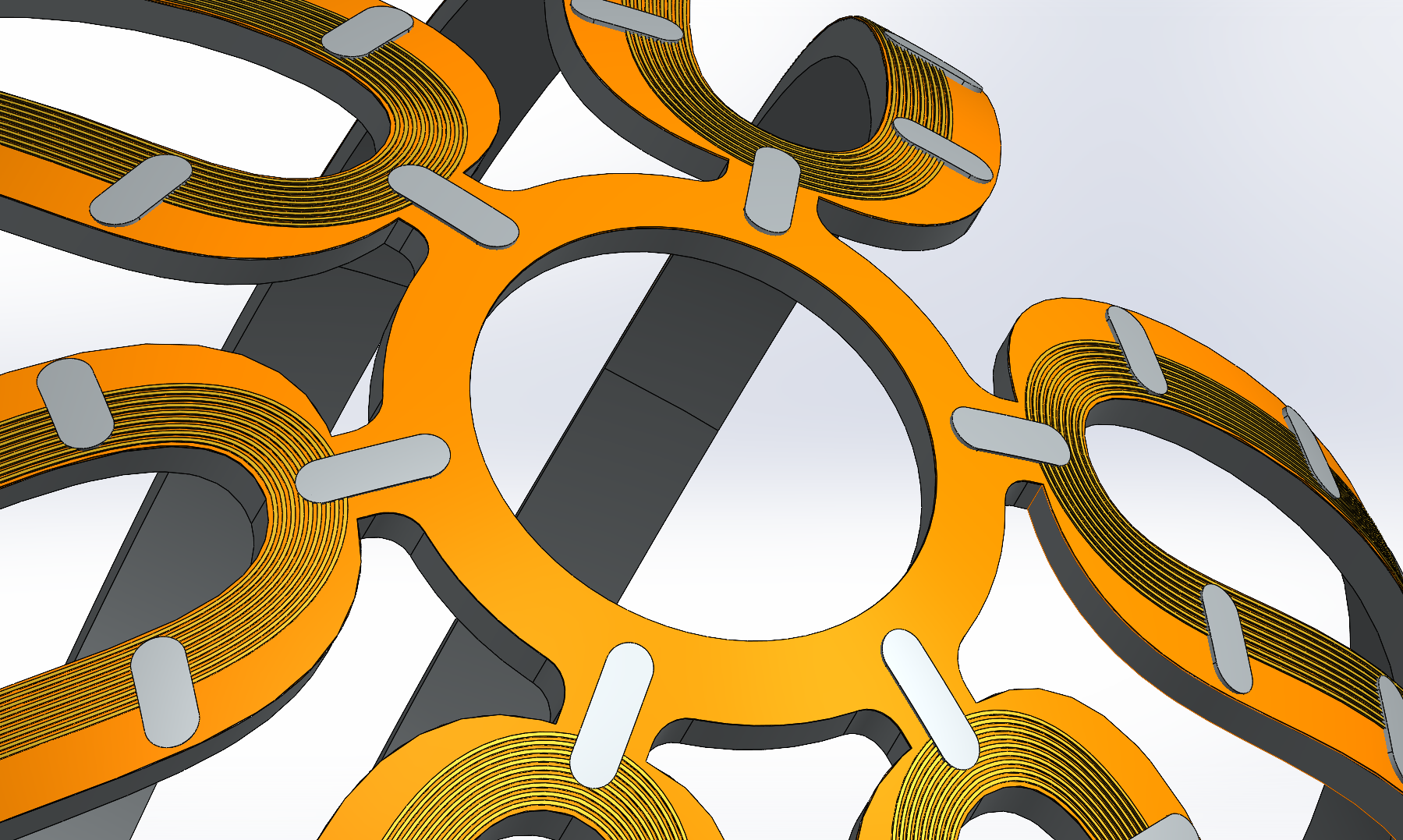

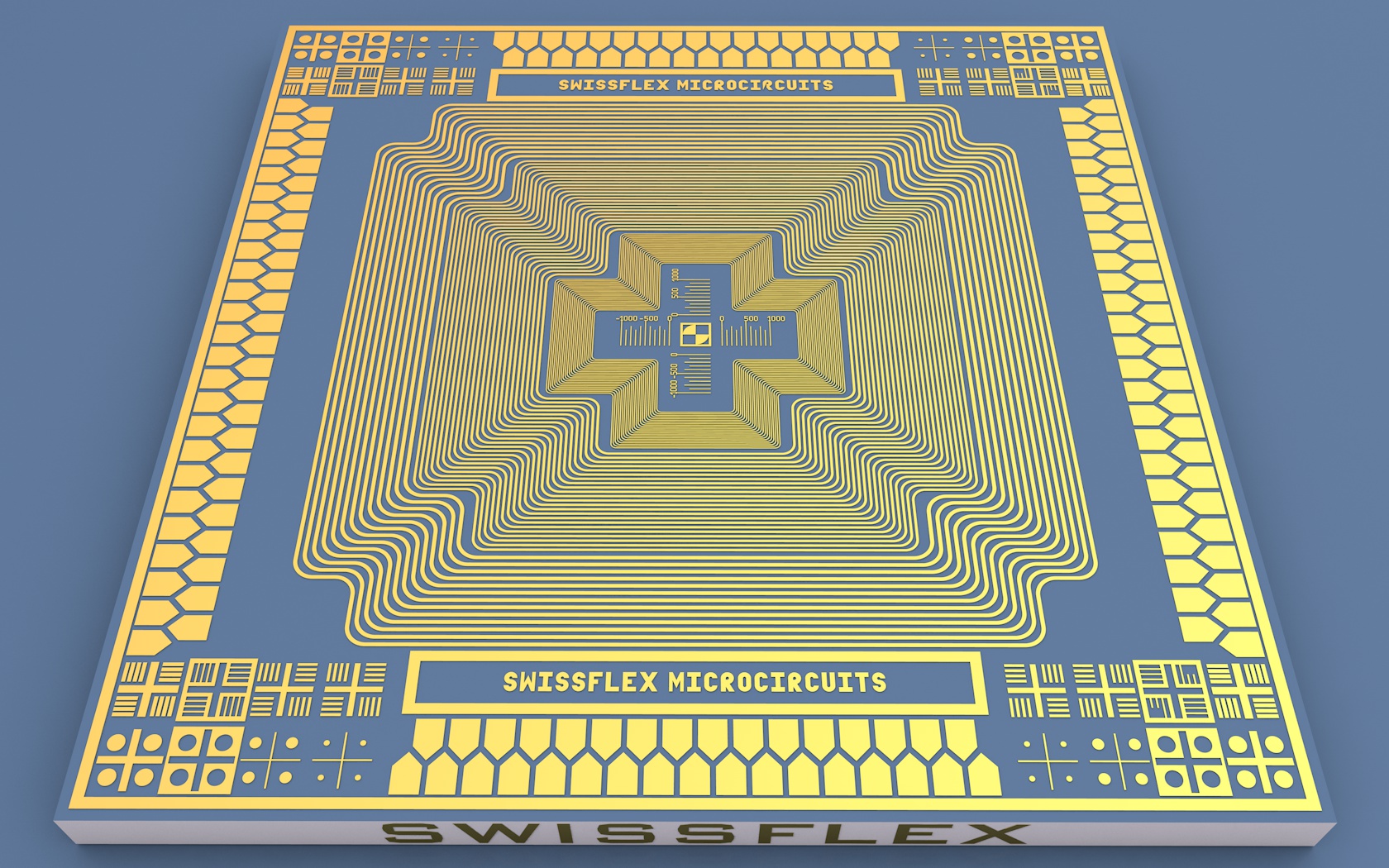

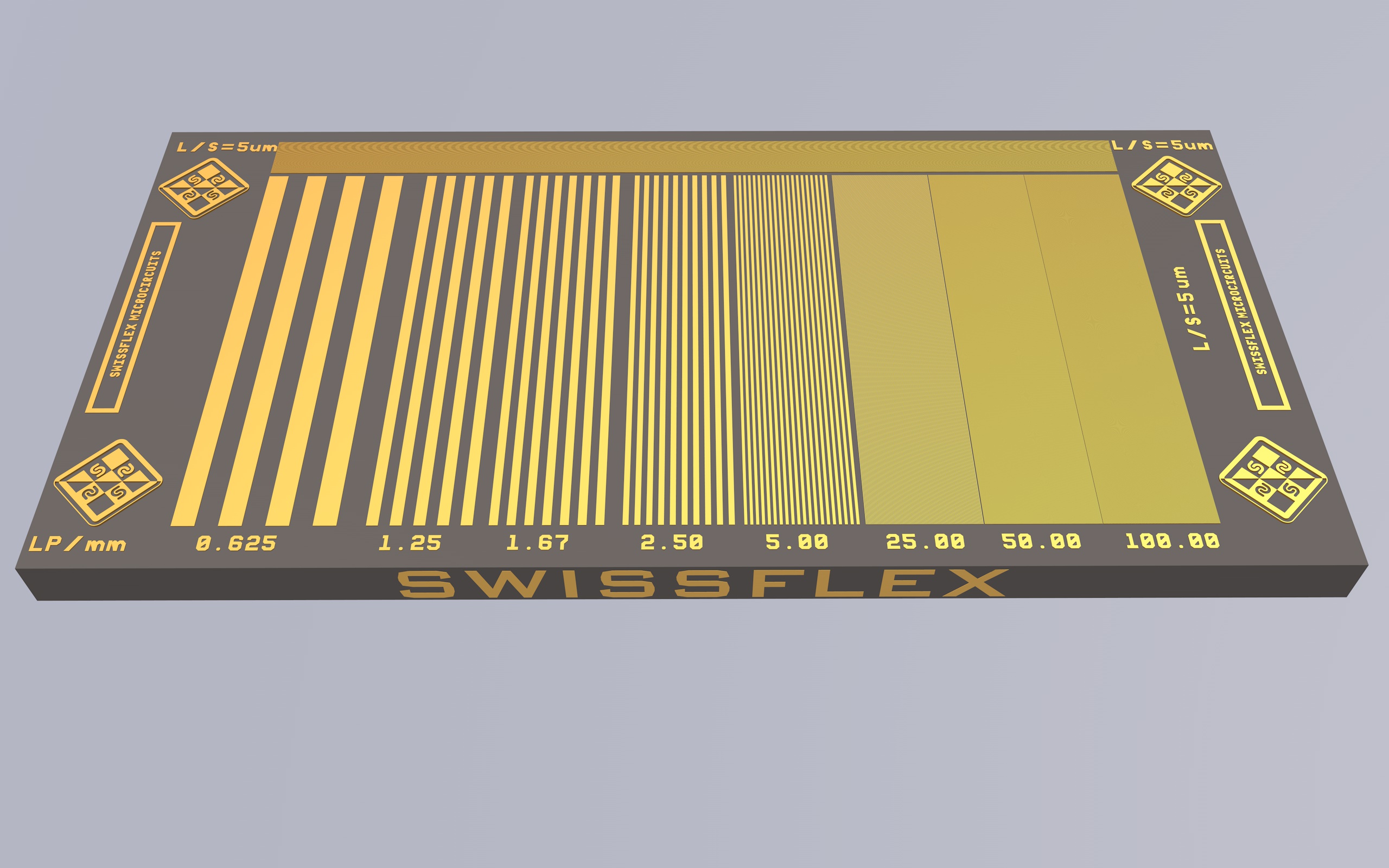

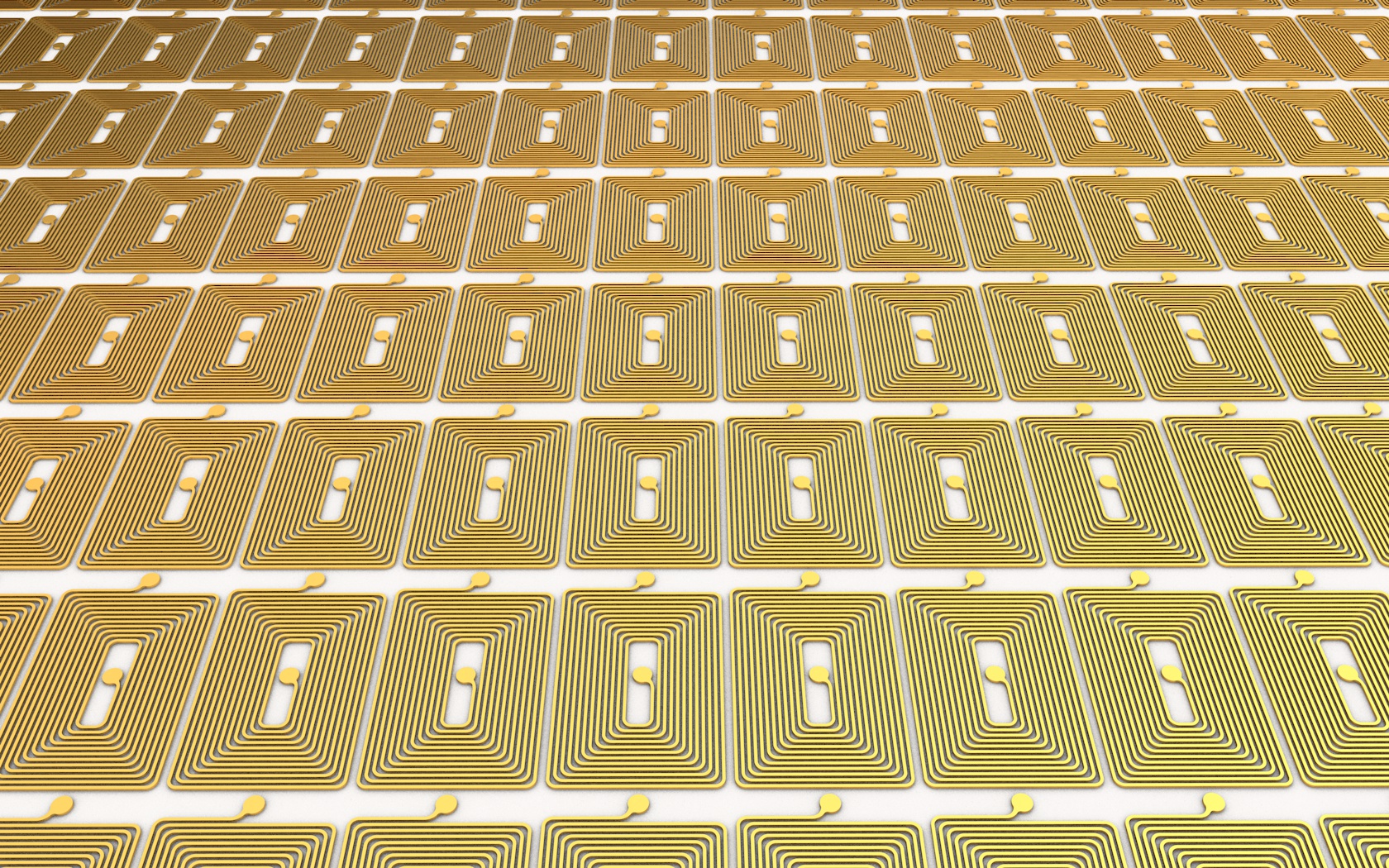

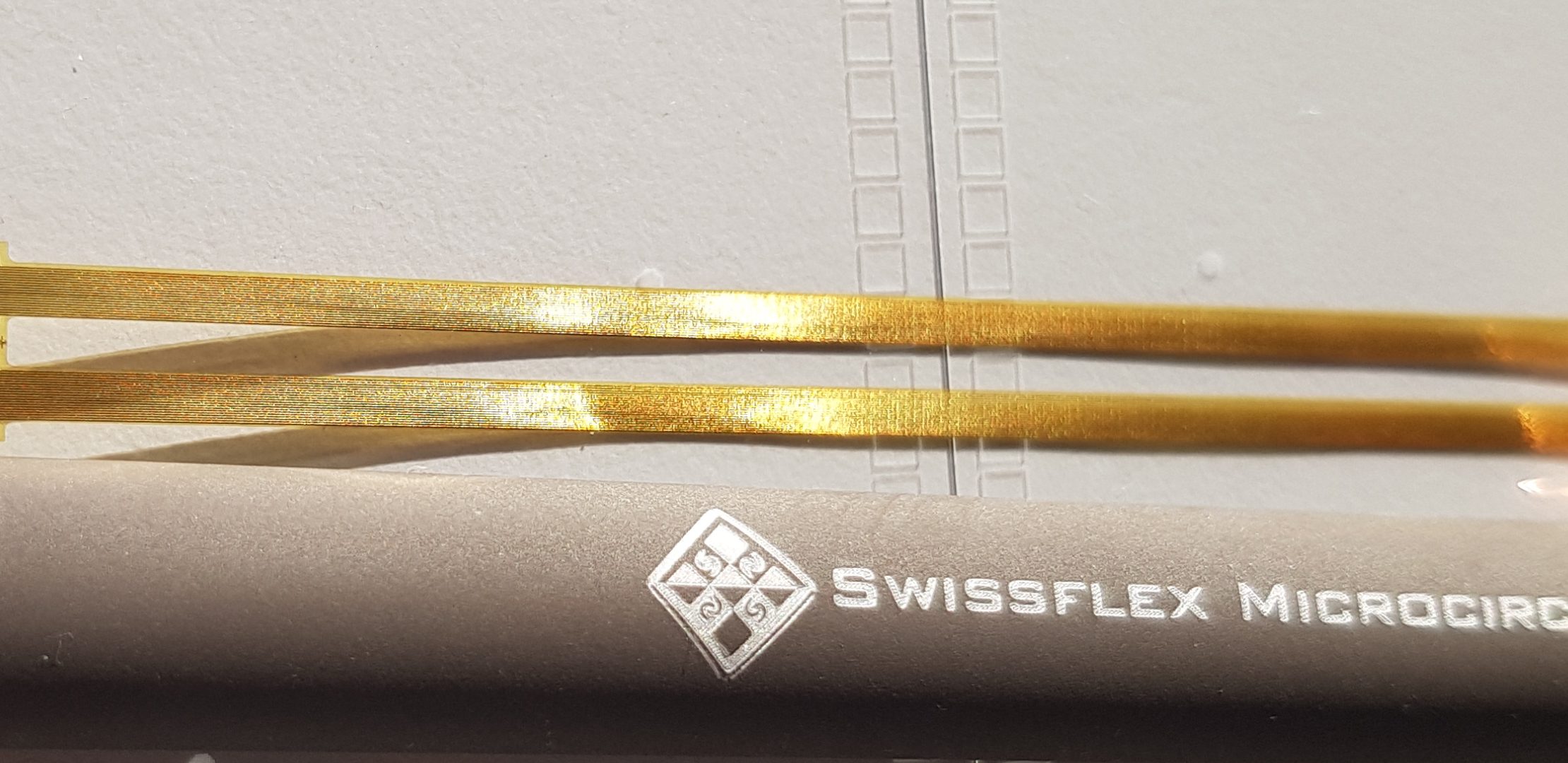

We assist you through the entire processes with development and manufacturing of innovative medical device technologies. We are involved with the design and development of medical products with multi-phase design process to deliver the best products possible to our customers. Your flexible microcircuits need to be dense and precise and tiny in size inserted into a catheter or wrapped around any object with smallest radius less than 20μm. There are only a few companies in the world who can handle it. We are manufacturing these microcircuits feature sizes ranging from 5μm to 20μm which consist of 6 multilayers. SWISSFLEX MICROCIRCUITS is an excellent factor and ensures high quality and control of all manufacturing processes in product servicing, by offering to our customers more engineering services with product design and development options, besides the existing manufacturing. We know the expectations of your industry and we understand your needs. Contact us, we will develop an individual solution for you. If we get involved right from the start and we will supply you the final solution with highly qualified and motivated employees. We will make it much easier for you to finalize your design, your product and your project. We will design and offer you the right solution for your requirements. When you choose SWISSFLEX MICROCIRCUITS as your thin film microcircuits manufacturing partner you get more than a professional design, manufacturing and processing facility at your service, you get to take advantage of integration the latest and most advanced innovation in your ultra flexible multilayer microcircuits and devices. SWISSFLEX MICROCIRCUITS offers an excellent performance, ultra-miniaturization solutions with no adhesives materials and highly conform to the requirement of implant and medical devices technology.

SWISSFLEX MICROCIRCUITS AG has a unique technology, which is a huge in advance to other technologies, in high density flexible electronics circuits which is excellent factor and ensures very high quality and control of the processes based on liquid polyimide on glass, ceramics and silicon substrates with ultra-miniaturization solutions, no adhesives materials, highly conform to the requirements of implant and medical devices technology.

We know the expectations of your industry and we understand your needs. Contact us and we will develop an individual solution for you.

ABLATION BALLOON CATHETERS – High density electrodes arrays on ultra thin flexible microcircuits for Diagnostic Catheters

MAPPING BALLOON CATHETERS – High density electrodes arrays on ultra thin flexible microcircuits for Diagnostic Catheters

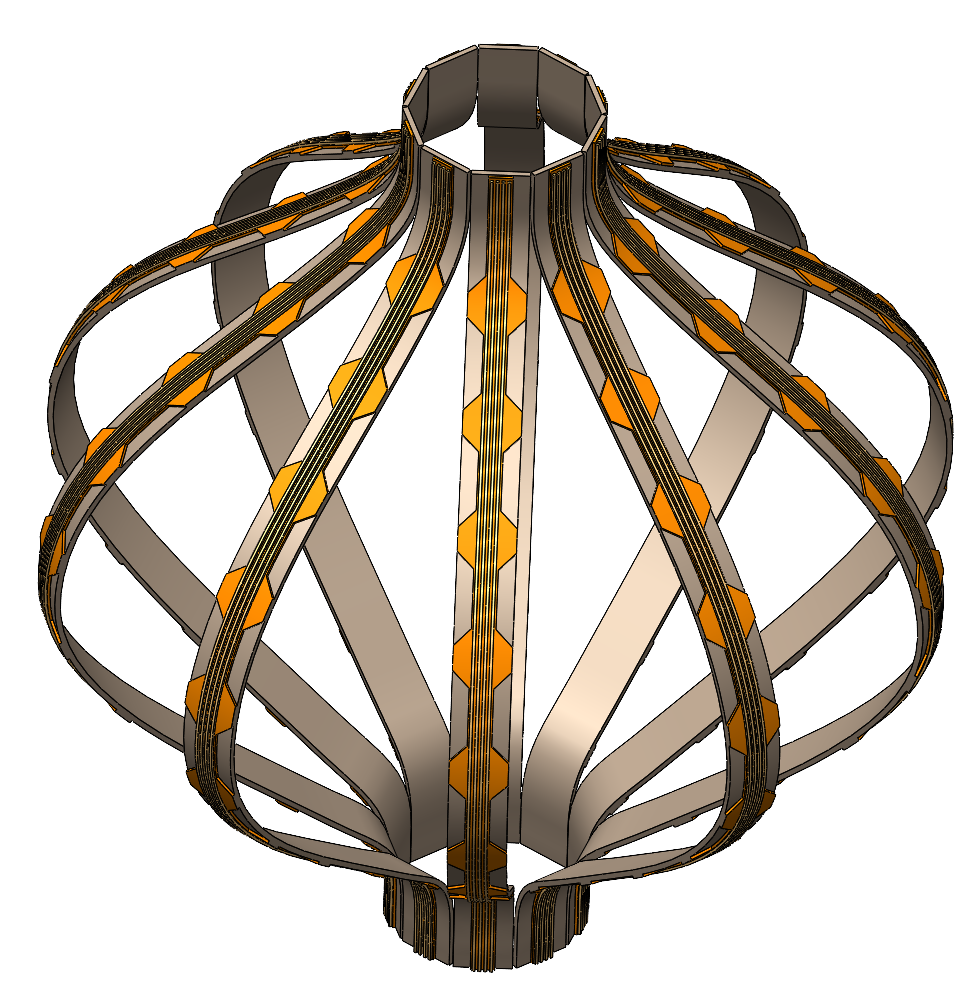

MAPPING BASKET CATHETERS – High density electrodes arrays on ultra thin flexible microcircuits for Diagnostic Catheters

ICE CATHETERS – High density electrodes arrays on ultra thin flexible microcircuits for Diagnostic Catheters

LUNG CATHETERS – High density electrodes arrays on ultra thin flexible microcircuits for Diagnostic Catheters

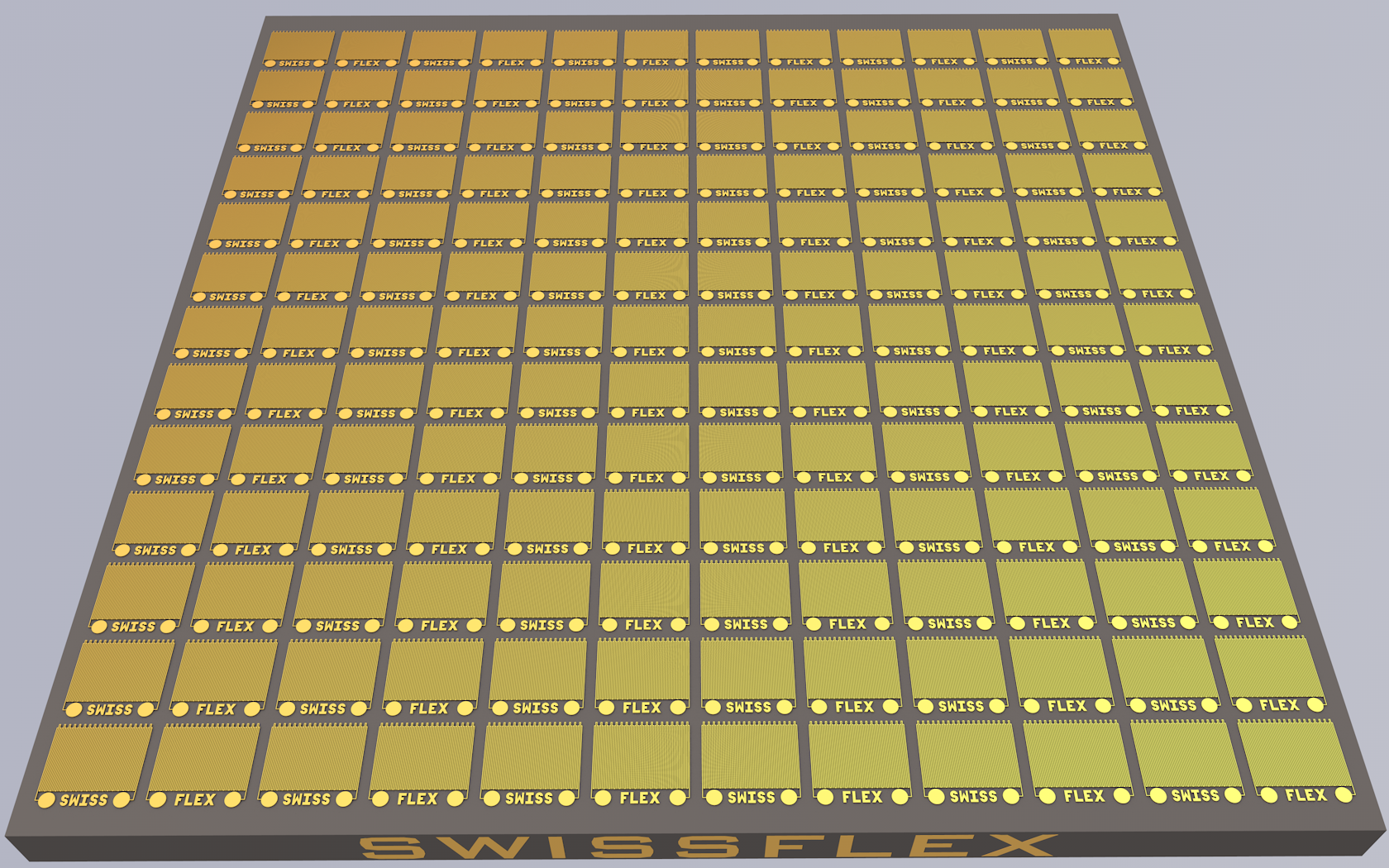

High Density Microelectrodes Arrays

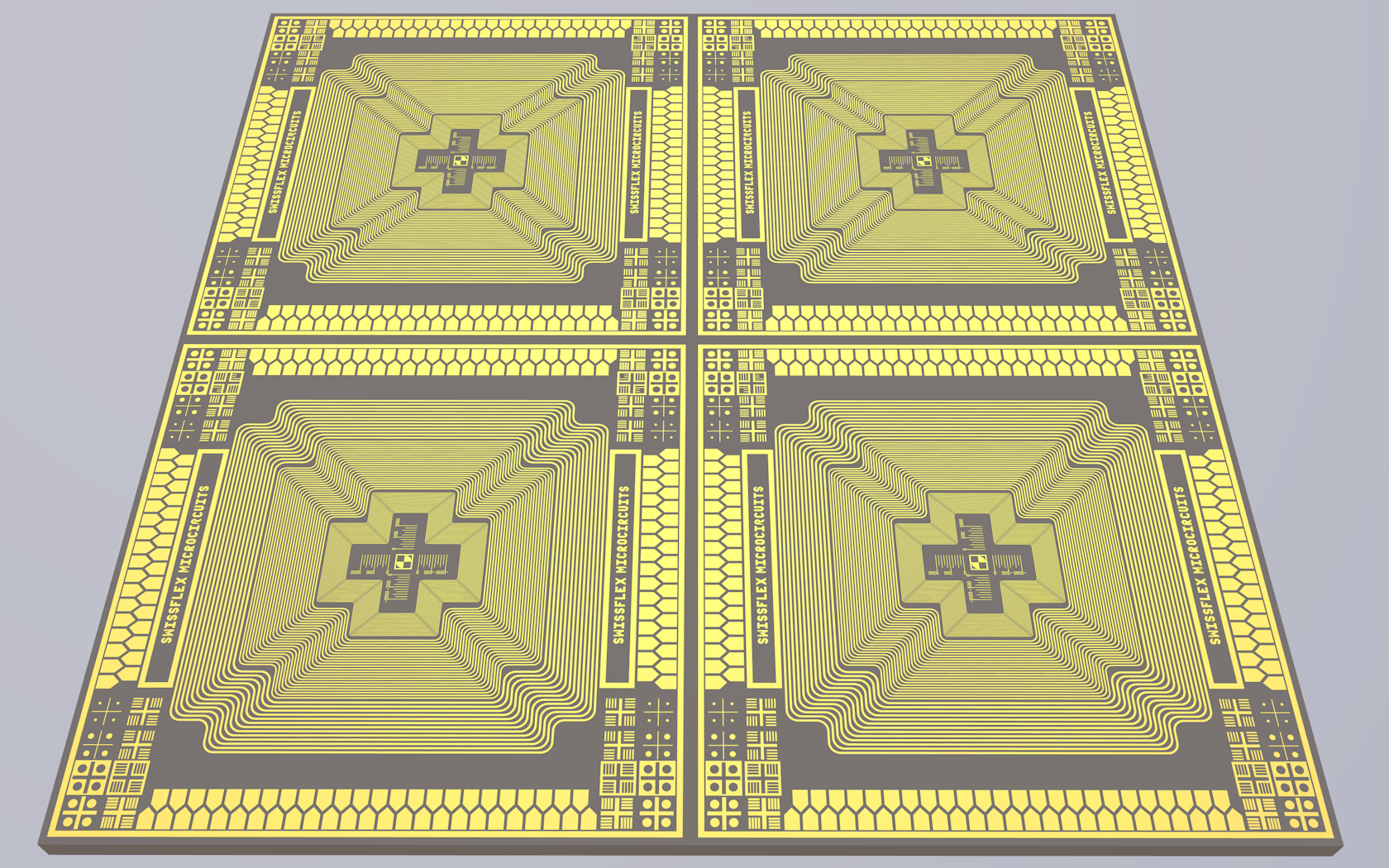

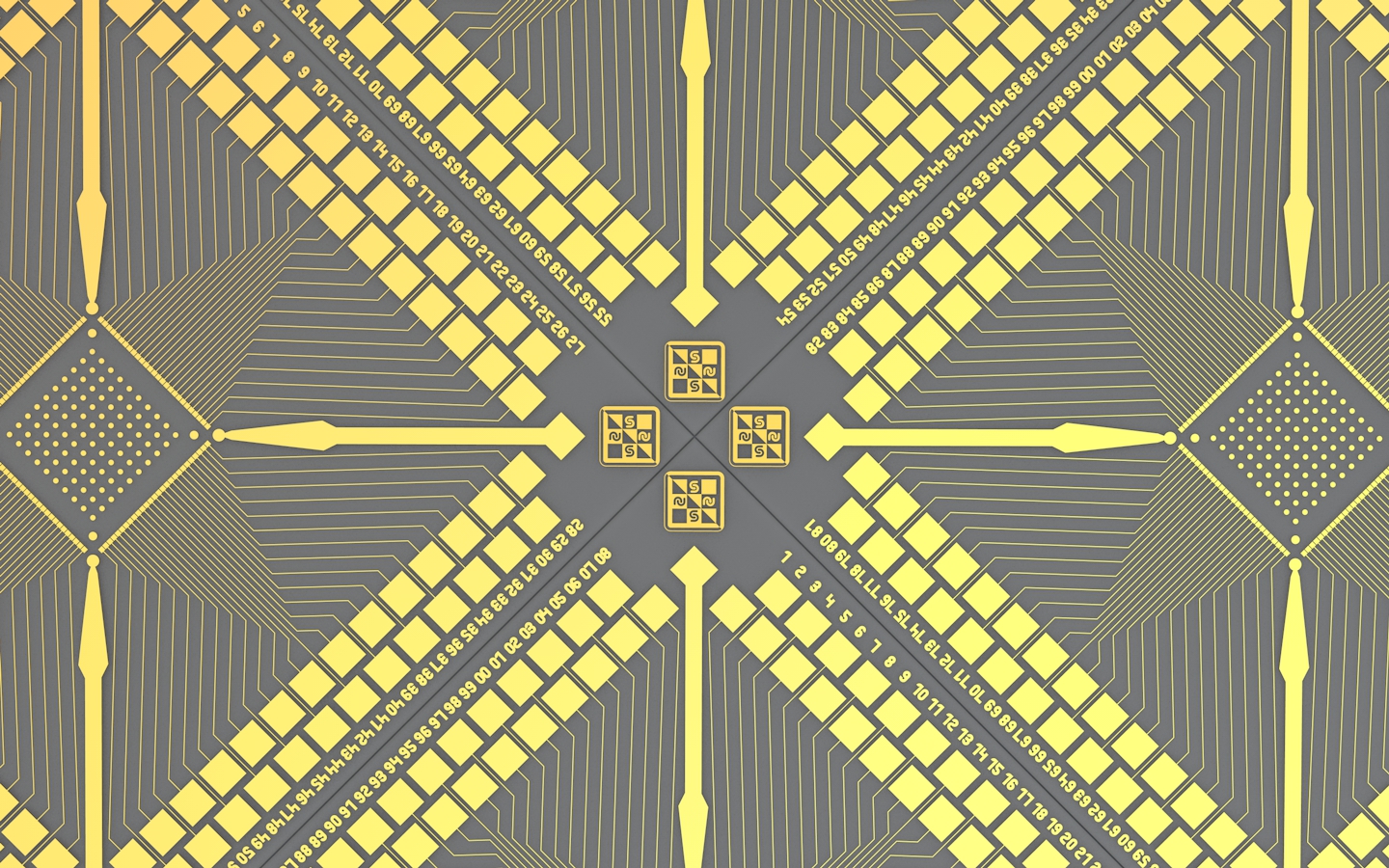

CAD Design and translation

Swissflex Microcircuits AG works with customer CAD data in DXF, AutoCAD DWG, Gerber, or GDS formats. We redesign, translate and repair customer CAD designs created in the different CAD systems in order to make it usable in manufacturing.

Photomask Layout & Design

Customer supplied CAD designs are plotted into a step & repeat pattern in order to maximize substrate yield and provide the lowest cost and highest quality thin film devices.

All substrates

All substrates following are available.

Photolithography

Photolithography is the process of using light to transfer images from a photomask to a coated thin film substrate. The key to the process is the use of a light-sensitive chemical called photoresist and a precision phototool, called a photomask. The photomask is custom tooling made from customer CAD files.

Photoresist Coat processing

Photoresist coating with enables patterning, is applied to thin film substrates via spin coating.

Polyimide Coat processing

Polyimde coating is applied to thin film substrates via spin coating. Polyimide offers the ability to build up multiple layers of circuitry.

Sputtering thin layer

Custom thin film metallization consists of sputtering metal layers with patterns made to customer specifications.

Swissflex Microcircuits AG is able to deposit a wide variety of films on many different substrate materials (Silicon, Glass, Alumina, Insulated Metal Substrates like Aluminium and Copper).

We are using 3 targets in-line sputtering systems in order to provide willing film quality and access to custom adhesion, barrier and conductive layers.

The target materials available at Swissflex Microcircuits AG include Chromium, Titanium, Copper, Gold, Platinum, Aluminum, Tungsten, Tantalum, Silver, and Chromium Nickel alloys.

Depending on the material selected needs, thin film sputtered layers can range from 25 nm for adhesion layers to 9um for conduction layers. Patterning is done to match customer specifications using wet chemical etch processes, dry etch processes, lift-off processes, liquid or dry photoresist processes, fine thin film line patterns and in circuit test measurement.

Electroplating

“ENIG” (Electroless Nickel, Immersion Gold) in which a Ni thickness normally 3-5μm layer of electroless nickel is given a thin gold ‘flash’ coating by immersion plating Au thickness 0,05-0,12 μm, an ion exchange process which coats the whole of the nickel surface. It means that ENIG is an electroless nickel layer capped with a thin layer of immersion gold.

ENIG is usually applied selectively on all Copper areas still free after soldermask printing (coated polyimide coverlayer or laminated yellow adhesive coverlayer).

Application of soldermask after ENIG plating processes is possible but not recommended for laminated yellow adhesive coverlayer or coated polyimide as coverlayer, because it reduces the adhesion during etching processes.

Laser microvias & Outline cut

Micro-vias are structures with laser with highly conductive, highly reliable interconnection between sub-multilayers.