TECHNOLOGY

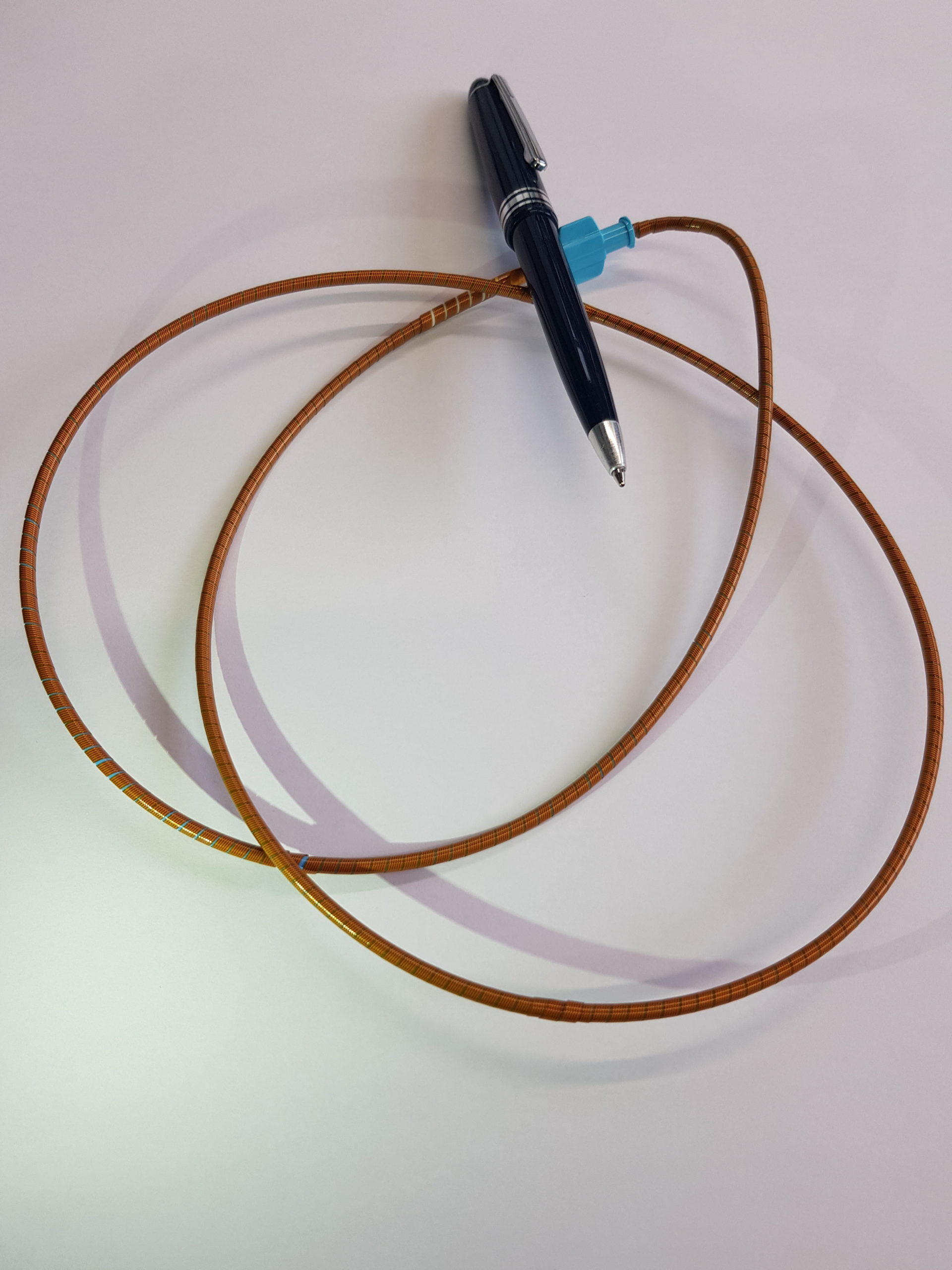

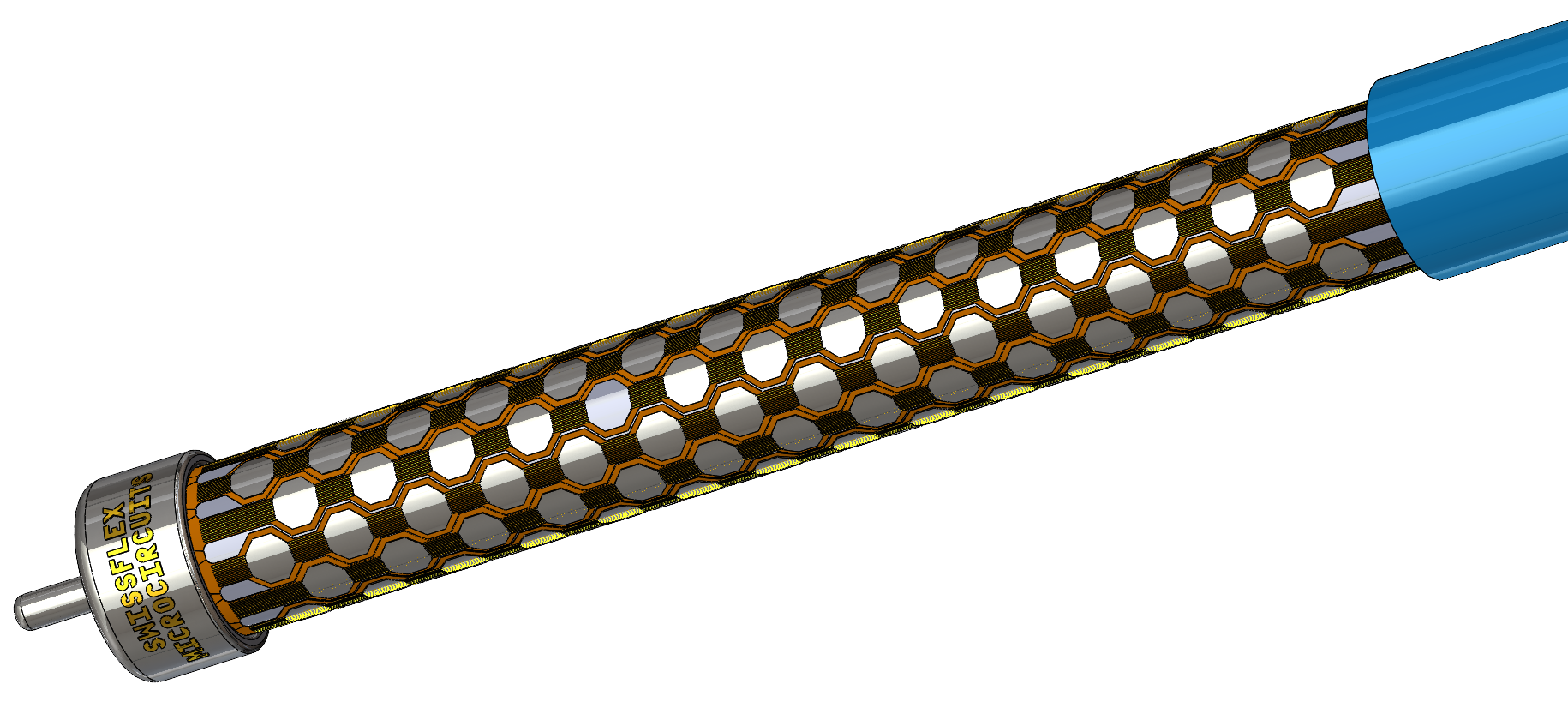

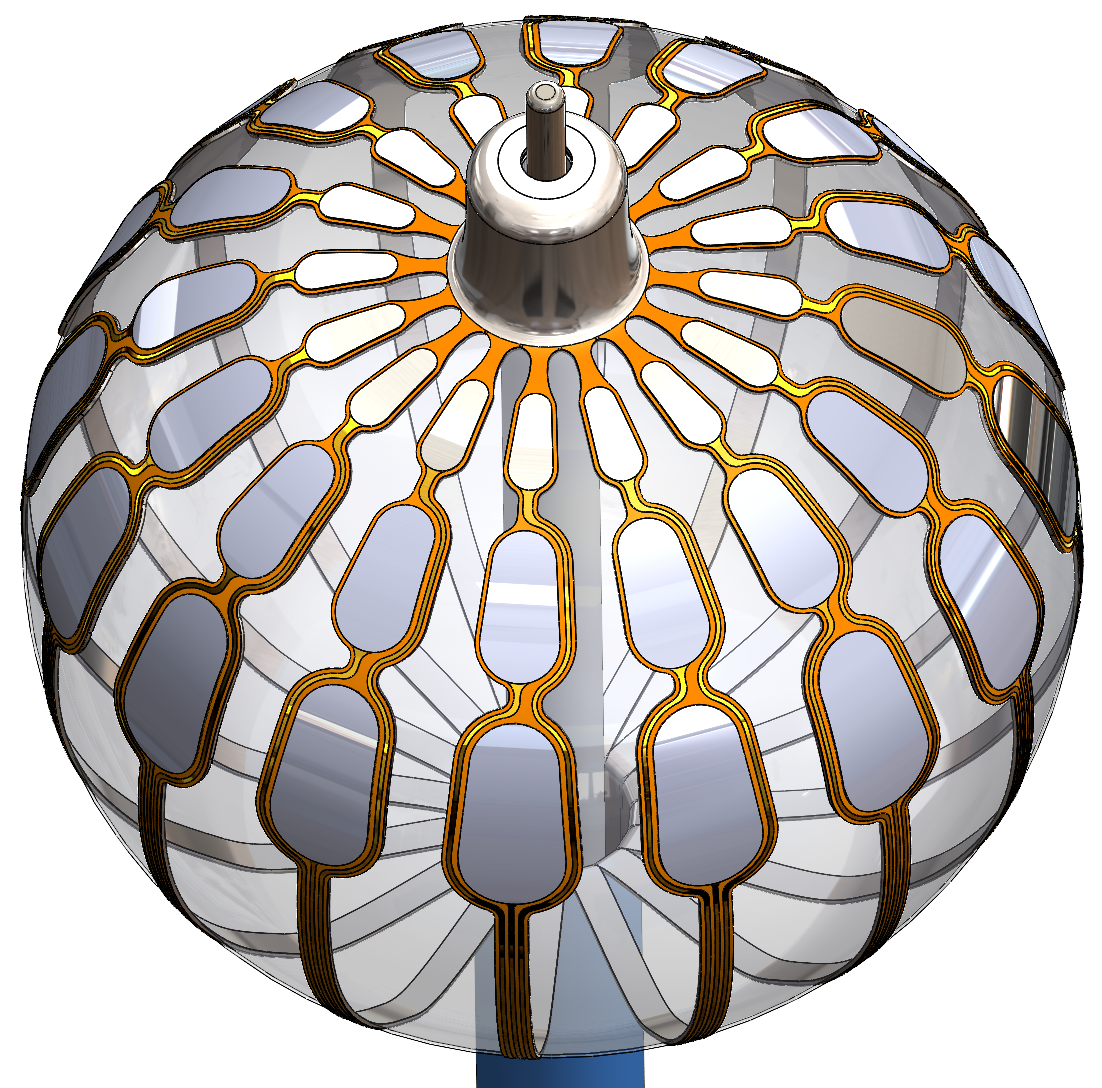

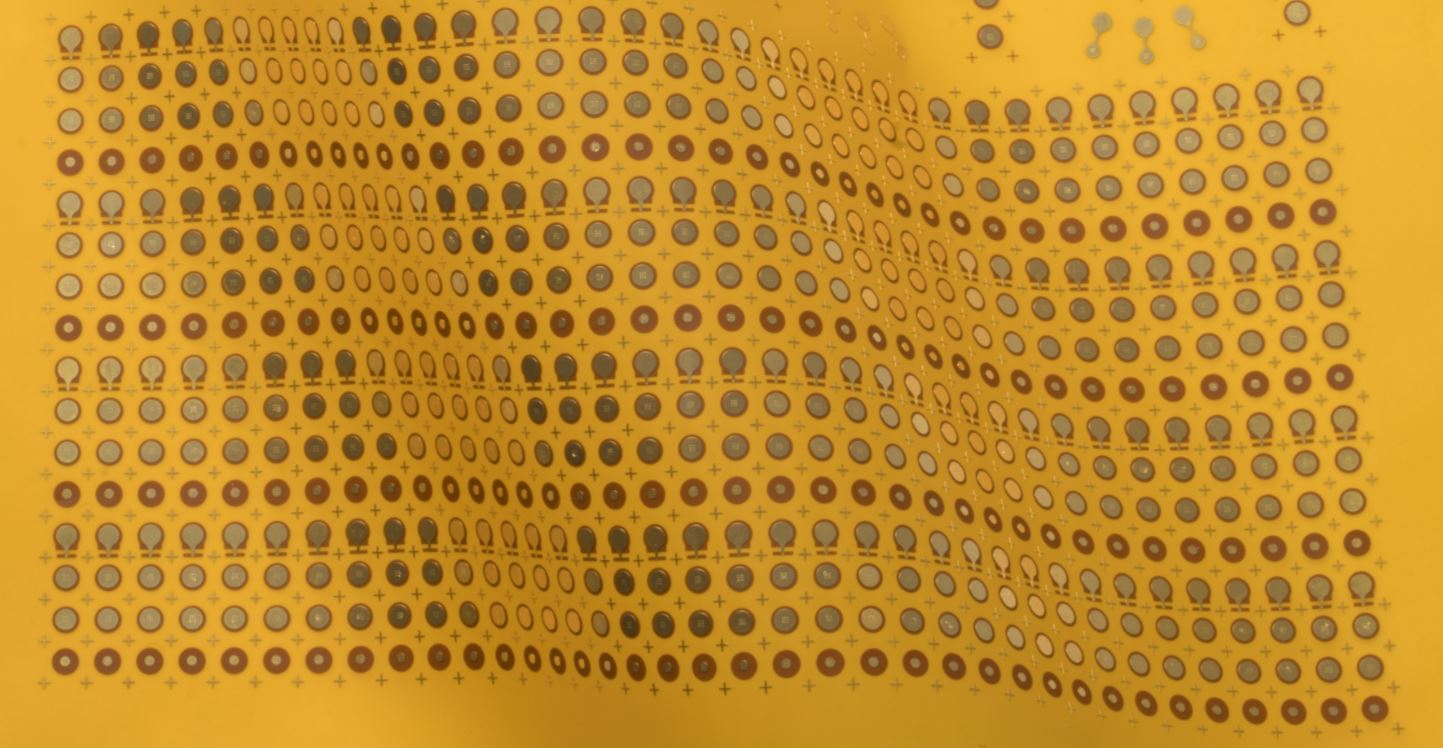

Smart Slim Flex technology has been developed with high value advanced proprietary technology demands of ultra-thin flexible hybrid multilayer flexible microcircuits to answer to our customer’s needs. It is characterized by a particularly ultra-thin structures, extremely small high density thin conductors, spacing and microvias, which are much more smaller than our indirect competitors.

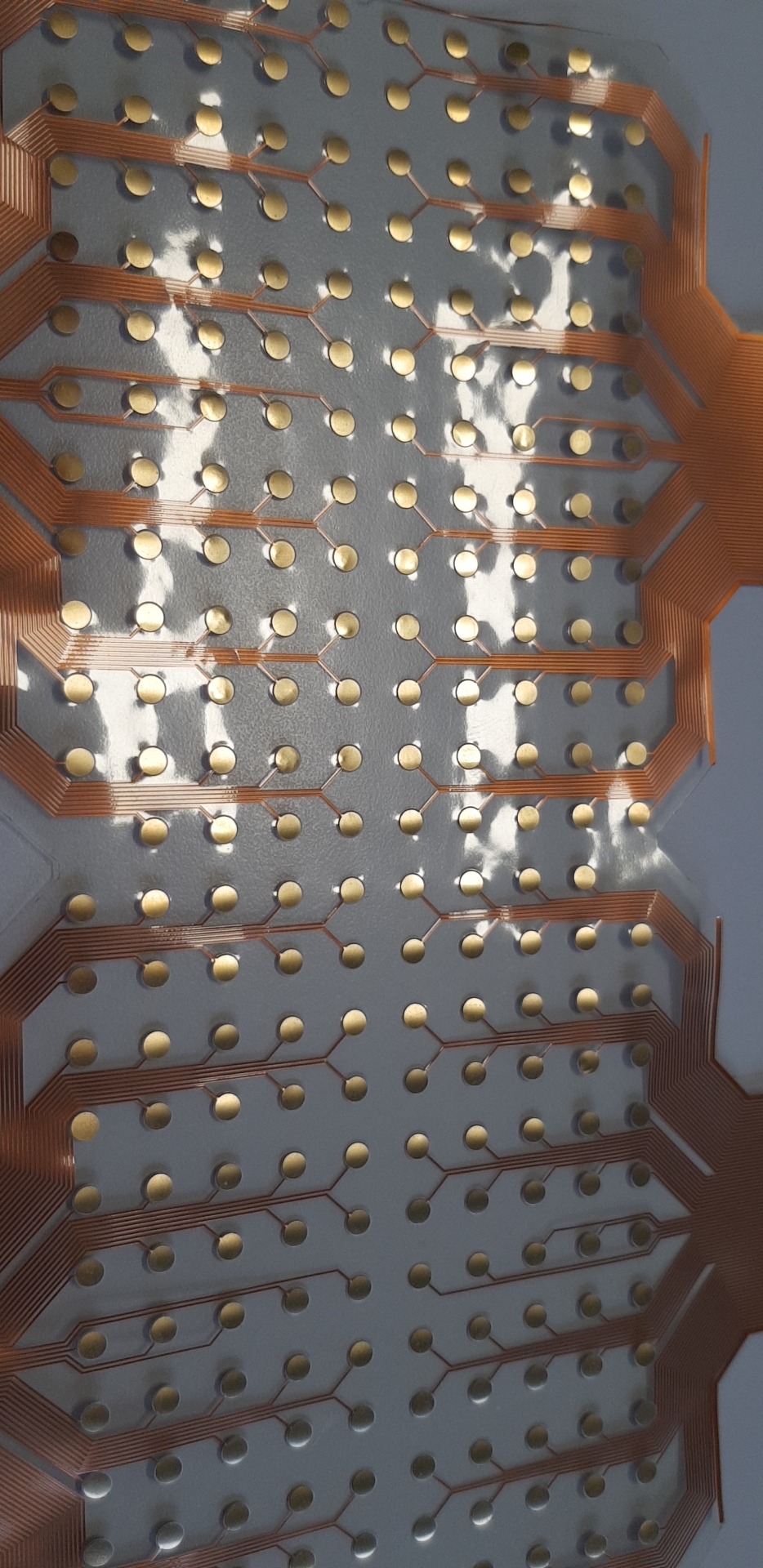

The Smart Slim Flex technology offers numerous technical advances over the existing flexible printed technology. It is highly flexible with very finely pattern-able interconnects with a pitch of 10 microns, integrated in complex products with high density structures up to 10 times more smaller with design and dimensional aspects in comparison with current flexible PCB technology on the market.

Our technology provides unlimited design possibilities, highly miniaturizing complex and ultra-compact highly in demand different technological applications.

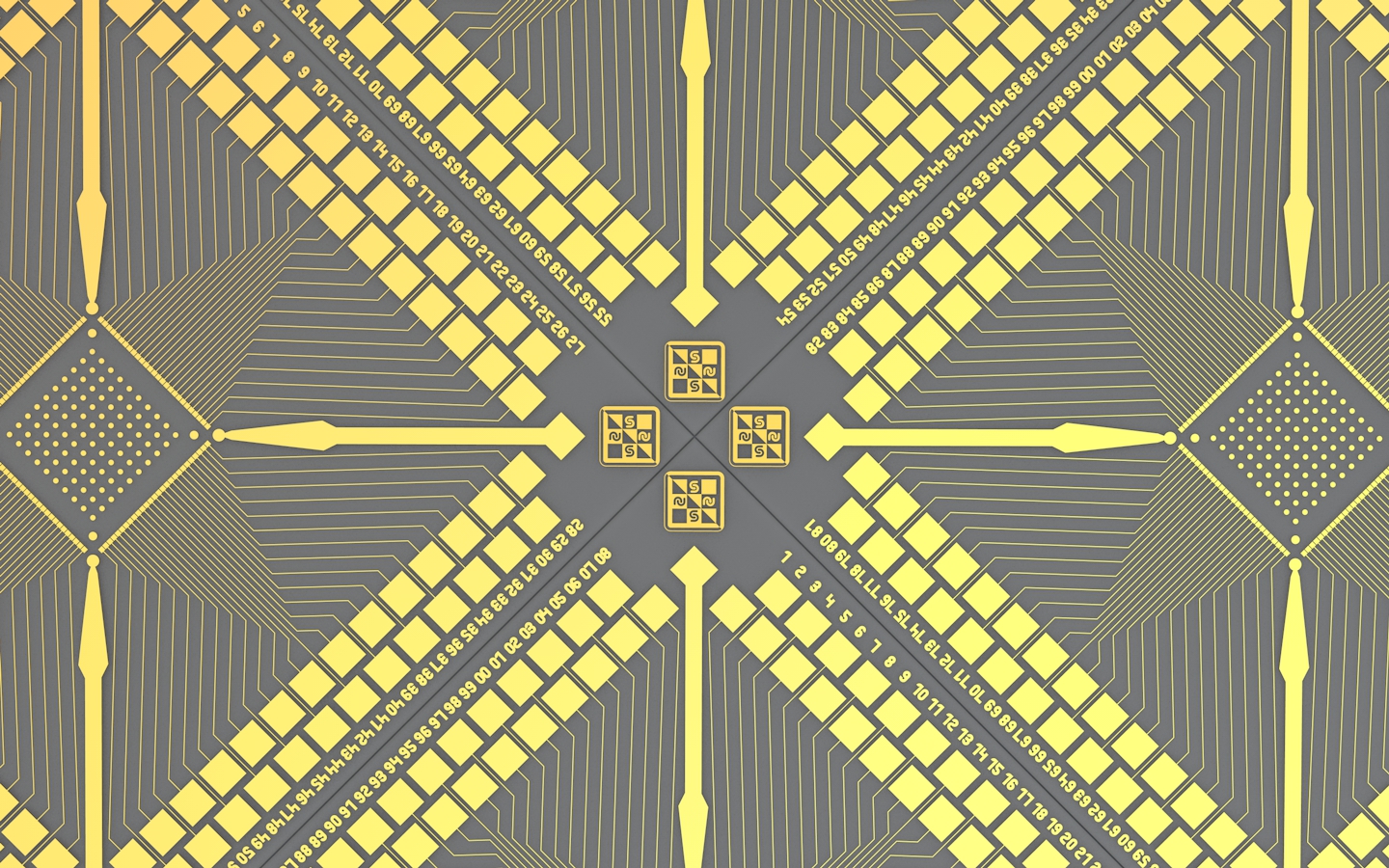

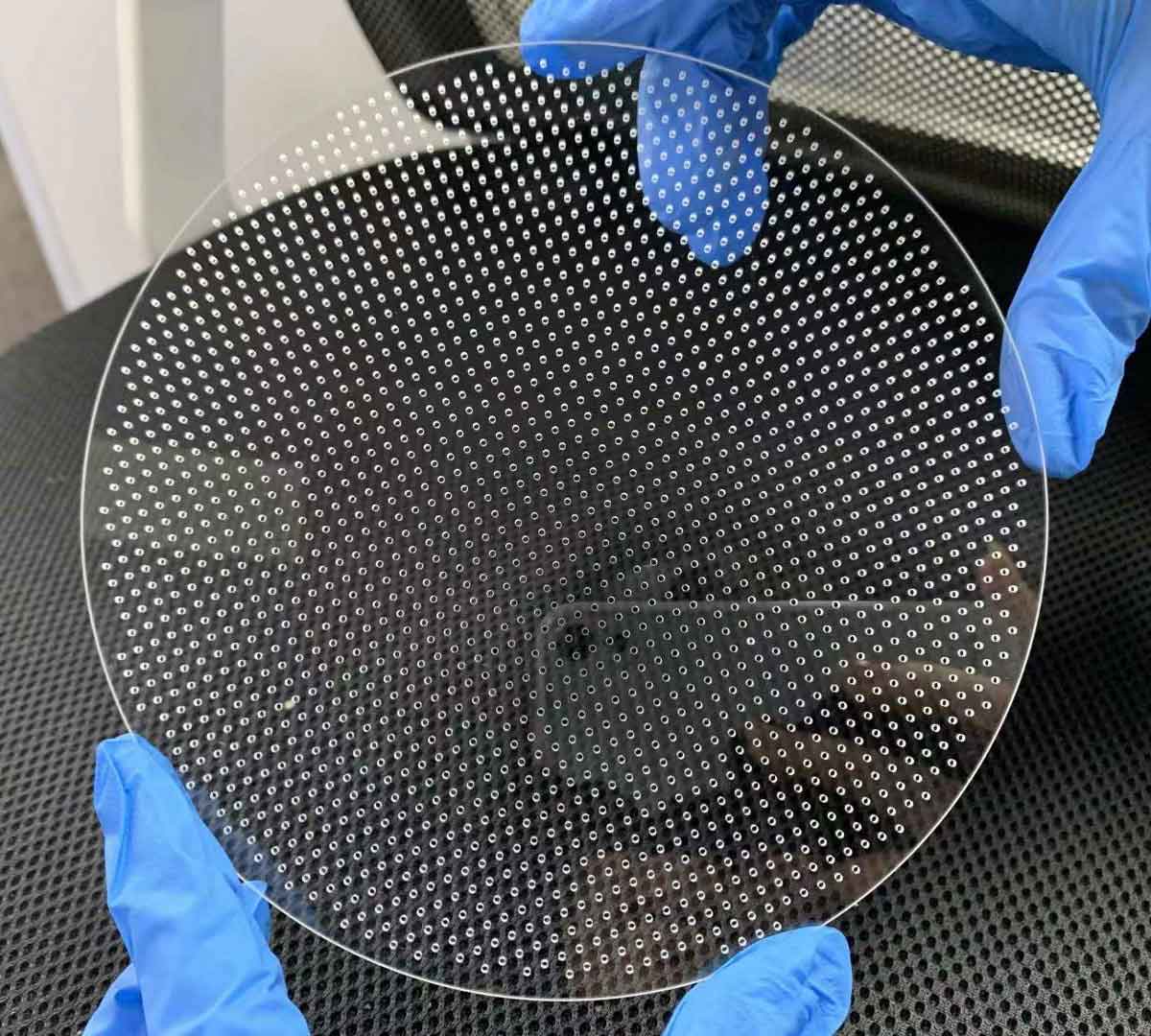

Through our semi-additive technology, we might be able to use a wide variety of metals in a wide variety of thicknesses as a current glass carrier material. However, this is not the only advantage of our Smart Slim Flex microcircuits technology. The microcircuit is assembled and tested on this carrier glass, ceramic or on others exotic materials.

In addition to used materials, the manufacturing processes is not only limited with our special polyimide chooses whose properties are not yet reached and are how all of these have been manufactured. Our polyimide degradation temperature is about 610°C and its chemical resistance is much higher than the usual polyimides with its expansion coefficient extremely low (comparable to silicon).

Actually, we are designing and manufacturing the prototype microcircuits with a wide choice of materials up to 5 layers including conductive layers in submicron levels (40nm to 12μm thickness) with high densities interconnection and a total thickness less than 60μm with very tiny and low weight. Our competitors produce 5 layers flexible circuit printing with a total thickness of 425μm.

We offer you the solutions technologies as well as innovation services applicable to both products and services. Your project can be big or small, stand-alone or have multiple partners, our expertise comes without question.

01. TECHNICAL STANDARD DESIGN RULES

02. MULTILAYER ULTRA FLEXIBLE MICROCIRCUITS MANUFACTURING PROCESSES

03. MICROCIRCUITS ON THIN & THICK GLASS TECHNOLOGY

04. MICROCIRCUITS ON THIN & THICK CERAMICS TECHNOLOGY

05. MICROCIRCUITS ON THIN & THICK ALUMINIUM TECHNOLOGY

06. HYBRID THIN & THICK FILM MICROCIRCUITS TECHNOLOGY

07. THIN & THICK FILM MICROCIRCUITS ON EXOTICS SUBSTRATS TECHNOLOGY

08. MICROSCALE ELECTROFORMING TECHNOLOGY MICRO-COMPONENTS TECHNOLOGY

09. CHIP ON MICROCIRCUITS & SYSTEMS TECHNOLOGY

10. ULTRA THIN STRETCHABLE MATERIALS & FLEXIBLE MICROCIRCUITS FOR WEARABLE ELECTRONICS TECHNOLOGY